Recently, FARO spoke with Kevin Kidd, Director of Software and Analytics at RFK Racing. RFK is a NASCAR-affiliated American professional stock car organization, to discuss the critical importance of quality control in competitive automotive sports. And by extension, its impact on the broader automotive technology industry.

When you’re racing at over 200mph (320kph), speeding past your competitors, accuracy and precision are twin essentials a competitive motorsports driver can’t live without. At peak performance, the vehicle must be in top form – all cylinders firing, the fuel line delivering, and every minute detail right down to the lug nut holders, radio box, and ducts for hose terminations/hose couplers all must be perfect.

Failure to achieve these automotive technology benchmarks isn’t just a minor inconvenience. It could mean disaster – injury or worse. More prosaically, it could also be the milliseconds that make the difference between a race win or a loss. That’s why quality control is so critical when it comes to professional motorsports, and why FARO, a global leader in digital reality solutions, can help enable what could be called a quality control revolution.

At its most basic level, quality control, as the term implies, is about ensuring quality in the parts that are produced. And that when multiple parts are operating together, the output is within acceptable tolerances. To accomplish this a variety of 3D metrology tools are employed: coordinate measuring machines (CMMs), portable coordinate measuring machines (with or without probing), laser scanning systems, optical measurement devices, or other advanced equipment.

In the world of competitive racing, quality control serves two key functions. That of designing & engineering and testing & validation.

The planning/blueprint phase begins with creating a computer-aided design schematic, or CAD model. This can be achieved by digitally sketching an early draft of a concept vehicle, or a CAD model can be created by scanning or probing a physical part augmented with sophisticated software programs processing the data. Once a new or improved part is built based on the model it can be scanned again to ensure that it aligns with the intended design - or, once tested, improved further still.

“Having access to world-class tools and software to build the top level of cars in the sport, and drive efficiencies within the organization is key,” Kidd said in reference to a recently announced partnership between FARO and RFK Racing, which includes a new FARO Tech Center and membership in the company's 'Tek Alliance.' “Our partnership is a perfect fit to allow our company to excel as the premier 'Tech' team in the sport and quality control is essential to that continued success.”

This testing and validation process happens throughout vehicle assembly and later, in real-world driving scenarios. Racing teams like RFK analyze components and systems to assess aerodynamics, handling, powertrain performance, and overall vehicle dynamics.

Testing includes:

When it comes to hardware, FARO Technology automotive technology laps the competition. That's because the company offers a wide array of quality control inspection tools designed to optimally measure every sized automotive component, from small parts like pistons and cylinder heads, to large parts like full vehicle bodies and chassis frames.

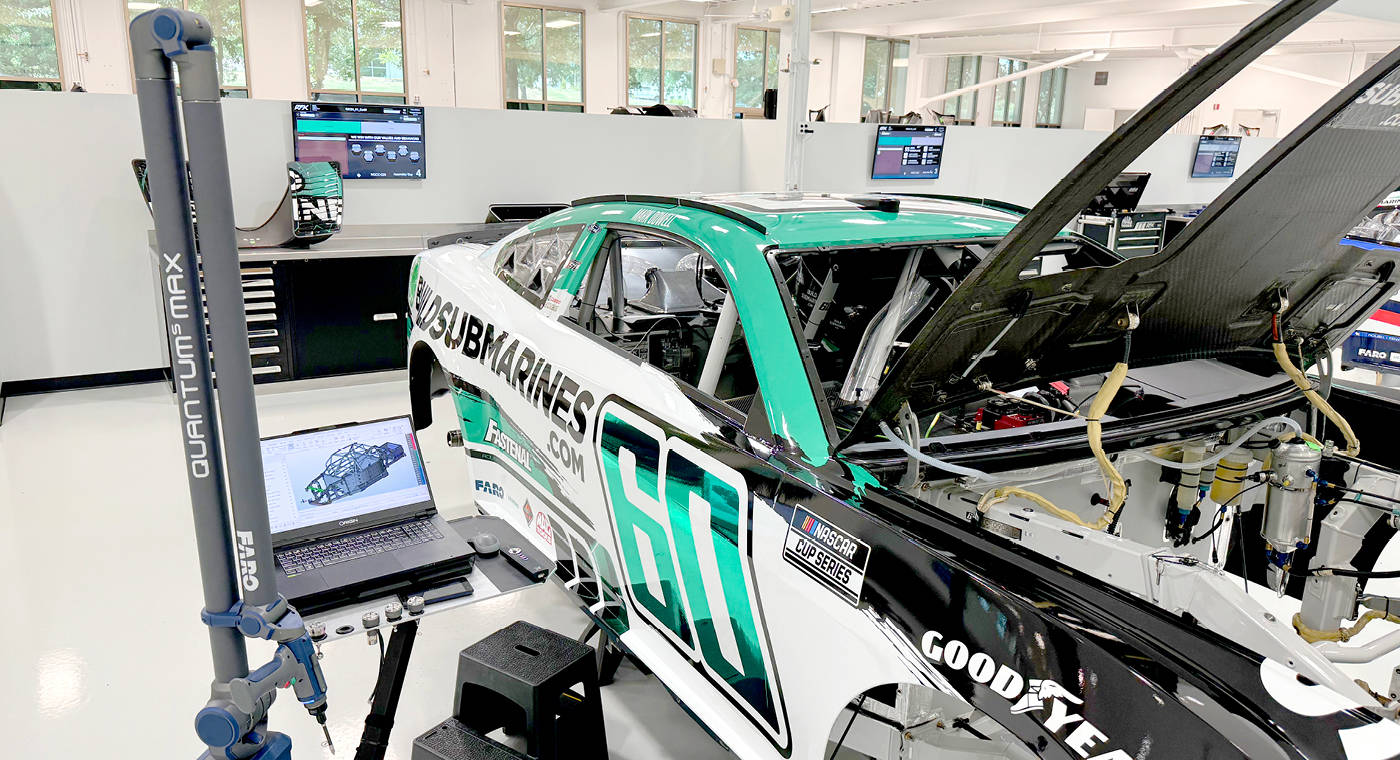

The Quantum S Max FaroArm, and its three hot-swappable LLPs, are designed to meet any measurement need. With maximum flexibility, extended arm reach and a redesigned end effector with dual kinematic LLP mounts, value and productivity is maximized by over 30%.

This will enable RFK to perform precision inspections and generate 3D scans for individual parts and fully assembled vehicle bodies.

The Vantage E6 Max Laser Tracker will be used for overall quality control of larger parts, including chassis, large body panels and floor components, and will be the primary tool used in vehicle setup prior to events.

Tools like this make on-site measurement of automotive technology fast and efficient, reducing inspection cycle times by up to 75%. Laser trackers measure 3D coordinates by tracking a target that the user moves from one point to another on the object being measured. In seconds, these measurements can be compared against nominal CAD data so teams can either make informed adjustments or move forward with confidence.

Pairing the two hardware's automotive technology capabilities also enables the RFK team to use multiple Quantum Max FaroArms for quality inspections in record time when necessary.

With its ability to automate tasks, analyze vast quantities of data, and enable communication between other programs and human operators, software empowers businesses and individuals to achieve higher levels of efficiency and productivity. That's especially true when hardware packages are paired with specific software offerings. From an automotive technology perspective, FARO's CAM2 Software and RevEng Software are excellent examples of this hardware-software synergy.

Not to be left out, FARO CAM2 Software serves as the backbone for these products.

Suited to manage repeat inspection routines, with live trend and statistical process control (SPC) analysis, CAM2 is designed for use with any FARO portable coordinate measuring machine (CMM), enabling operators to capture accurate measurements.

Last, RevEng Software's ability to transition 3D scans into CAD models in record time will enable RFK to quickly reverse engineer needed parts.

“As the director of software and analytics my mission is to leverage my expertise and passion for vehicles, automotive technology, and vehicle dynamics to create innovative and competitive solutions that enhance the speed, safety and sustainability of our racing operations,” Kidd said. “The Quantum Max in combination with CAM2 and RevEng helps achieve that aim. I really can't imagine working without these powerful software tools at this point.”

Quality control's greatest applicability isn't so much the individual race car but rather a rapidly evolving automotive technology industry, that above all, places people above parts.

But to do that, the parts must be perfect.

It all goes back to what NASCAR calls the “Next Gen Car,” or “Gen-7.” The goal is to modernize race car design, enhance on-track competition, reduce costs for teams, and increase relevance to manufacturers and fans. Naturally, this has resulted in a more advanced, competitive environment across the racing industry.

Now more than ever, each part must be inspected at a higher level of accuracy and precision. It is this granular understanding of parts that will lead to improved performance, and strict adherence to NASCAR regulations. For a company like RFK, it will also feed other critical processes like multi-body vehicle simulation, PLM history, and optimization of completed vehicle assemblies per racetrack.

“In this day and age of NASCAR, the finest level of details in every facet makes the difference in our team's ability to compete for and win races and championships,” Kidd added. “Without quality control ensuring vehicle safety and topnotch vehicle performance, there would be no professional racing and there wouldn't be NASCAR.”

Subscribe to the blog for the latest updates