A recent article by Global Mining Review, in collaboration with Markus Handl from RIEGL Laser Measurement Systems, highlights the versatility and precision of the RIEGL VZ-series scanners. This advanced device is designed for both static and mobile use, capable of measuring distances from 0.5 meters to 1000 meters with remarkable accuracy.

The ability to detect changes in terrain is a crucial aspect of efficient monitoring in the mining industry. Traditional monitoring methods include radar measuring systems for surface change detection and robotic total stations for monitoring prisms or reflector targets. Terrestrial laser scanners have emerged as a highly effective tool for monitoring in mining, offering a significant advantage in terms of accurately detecting even the smallest terrain changes and monitoring critical areas with prisms.

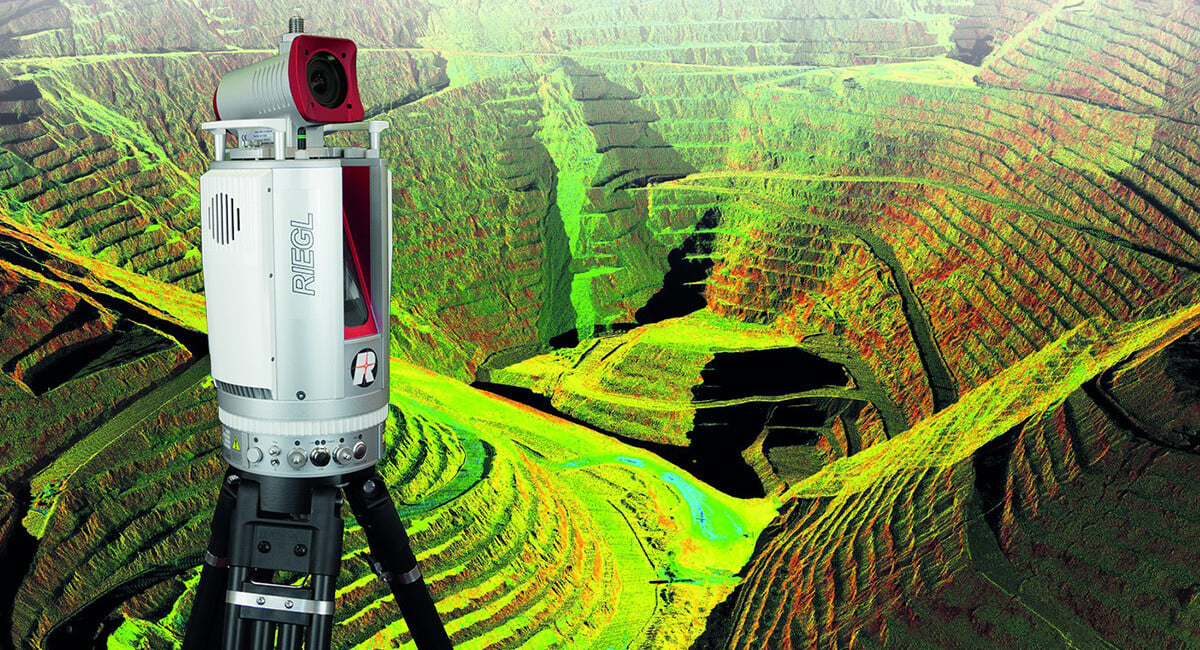

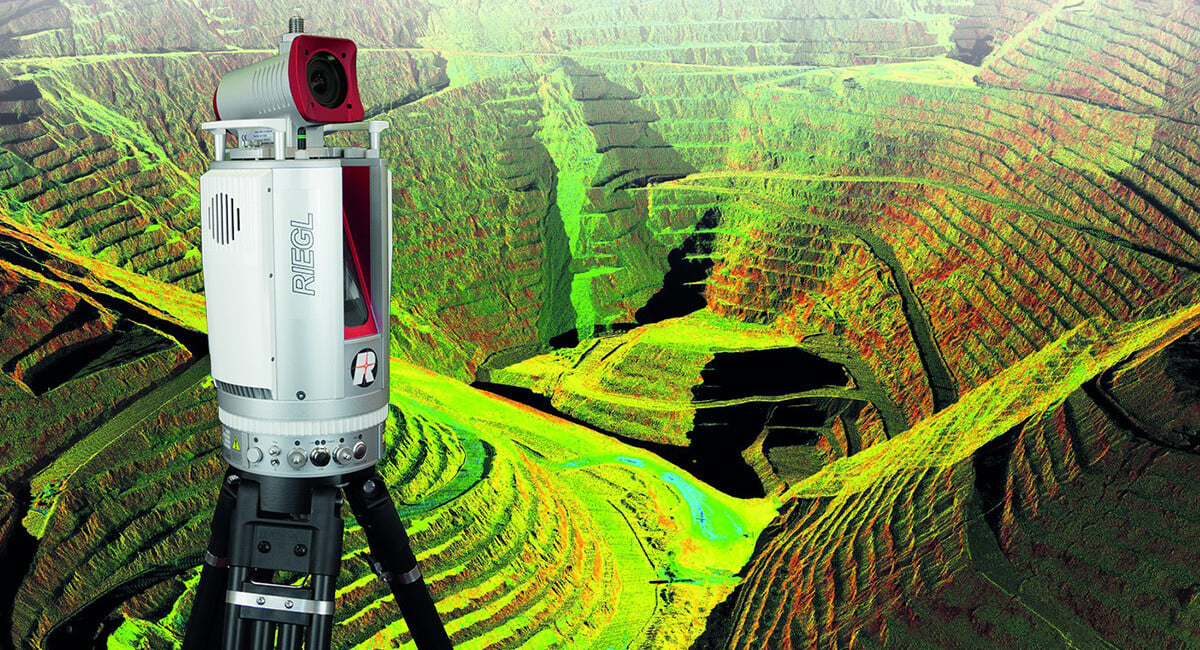

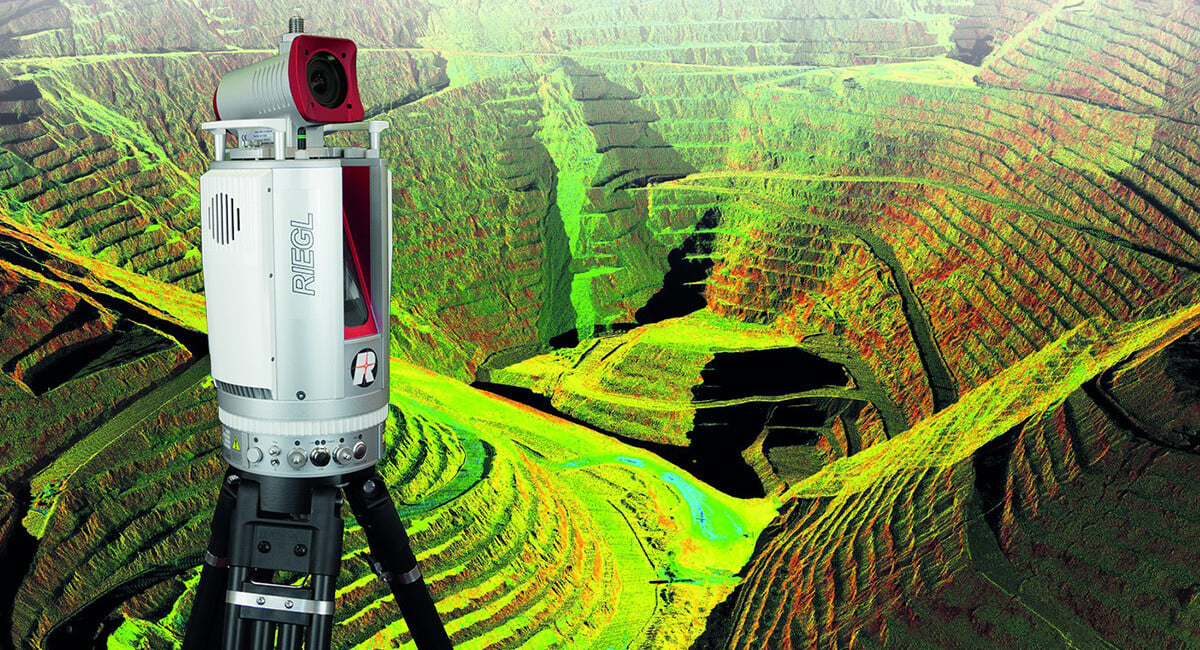

RIEGL Laser Measurement Systems has developed monitoring solutions based on RIEGL 3D terrestrial laser scanners which can be utilised for many purposes, such as the monitoring of mountain slopes, landslides, and all kinds of mining operations (see Figure 1).

Figure 1. RIEGL VZ-2000i 3D terrestrial laser scanner utilized for slope monitoring purposes.

Figure 1. RIEGL VZ-2000i 3D terrestrial laser scanner utilized for slope monitoring purposes.

In response to customer feedback, RIEGL has developed the Monitor+ App, which builds on the already existing monitoring applications, including the Monitoring App, the DesignCompare App, and the SlopeAngle App (see Figure 2).

Figure 2. Overview of RIEGL’s monitoring applications

Figure 2. Overview of RIEGL’s monitoring applications

The Monitor+ App offers users the ability to temporarily interrupt the monitoring process, utilise the scanner for alternative tasks, and resume monitoring at their convenience. Furthermore, the application now includes the capability to monitor prisms. This flexible solution offers a cost-effective and highly productive way to use the 3D laser scanner, ensuring accurate monitoring of an entire mining area. The acquired data is processed directly on board the scanner in real time, and the results are displayed promptly via a web viewer. No additional software or computer is necessary to view the results, as the data is fully evaluated automatically on the laser scanner.

Full flexibility for monitoring projects In monitoring, the ability to adapt the use of monitoring systems is a significant benefit. It is essential to conduct surveys in specific areas at designated intervals to avoid unnecessary costs associated with idle time. In developing the RIEGL V-Line Monitor+ App, close attention was paid to customer feedback, resulting in the development of a highly flexible monitoring solution. The ability to perform sporadic and periodic monitoring enables the scanner to be utilised for other projects between the execution of monitoring scans. This may include further monitoring projects or 3D surveys of other mine areas. If an area should be monitored permanently, the laser scanner can also be set up for 24/7 monitoring. In this case, an uninterrupted operation and remote access from the control centre is essential.

Therefore, the RIEGL V-Line CB23 communication box was developed to ensure seamless 24/7 operation of the scanner. An integrated LTE router with a pre-installed VPN connection allows for secure remote access to the laser scanner and all hardware components of the box. With this safe remote connection, the results processed on the scanner can be monitored by the mine control centre, enabling prompt action at any time. A hardware watchdog monitors the hardware components of the box with the objective of ensuring uninterrupted operation of the scanner and all components. External sensors that are attached to the communication box measure temperature, air pressure, and humidity and ensure highly accurate laser measurements, especially over very long distances. The RIEGL V-Line UB23 is also integrated into the communication box, enabling full utilisation of all RIEGL monitoring applications also with older RIEGL VZ series scanners.

Figure 3. Coloured pixels show the surface change in the web viewer. The activated cluster analysis groups spatially connected pixels into larger clusters

Figure 3. Coloured pixels show the surface change in the web viewer. The activated cluster analysis groups spatially connected pixels into larger clusters

Figure 4. The web viewer’s display of the panorama image allows for a more effective interpretation of the monitored area. The activated selection analysis shows the surface change of the selected area

Figure 4. The web viewer’s display of the panorama image allows for a more effective interpretation of the monitored area. The activated selection analysis shows the surface change of the selected area

In addition to surface changes over time, monitoring in opencast mines also requires surface comparison to a given design model and analysis of slope angles. The Monitor+ App unifies the features of the DesignCompare App and SlopeAngle App, offering users full flexibility in one application. DesignCompare analysis detects overcut and undercut in the mine by comparing the actual state with a design model. SlopeAngle analysis automatically calculates the slope angle of the scanned area and highlights critical slope angles to ensure that the slope angles of stockpiles and dumps remain within specified limits.

To guarantee the utmost flexibility when setting up the monitoring project, a configuration wizard is used in RiSCAN PRO, RIEGL’s software for processing and visualising terrestrial laser scan data. This wizard guides the user through each step of the configuration process. The user is able to define desired monitoring areas, the prisms/reflectors to be monitored, and the associated scan schedules. Additionally, the scan resolution, threshold settings for the change visualisation in the web viewer, and alignment settings are defined. Automatic scan position alignment is mandatory, in case the monitoring is interrupted and the scanner is temporarily removed from the monitoring site.

The acquired data is processed directly on the laser scanner’s processor, where the 3D point cloud is transformed into a standard image representation, with range values coded in the RGB channel and local normal vector of terrain coded in the alpha channel. The results are displayed in the Web Viewer, which enables the user to read out the change information for each analysed image pixel. This viewer can be accessed either locally on the scanner or uploaded to a web server, where it can be viewed by multiple individuals.

As illustrated in Figure 3, users can navigate through the various epochs in the Web Viewer. Changes to a specified reference scan are displayed colour-coded according the selected colour tables and threshold values. To enhance the visualisation of the terrain, the surface can be shown as shaded relief by utilising the information of the local surface normal vector. The activated cluster analysis groups spatially connected pixels into larger clusters. By setting pins in the desired clusters, users can access change information, including area change and volume change.

If an area is of specific interest, it can be selected in the Web Viewer using the selection analysis tool and all information on the surface change of the desired area is also displayed (see Figure 4). Another new feature of the Monitor+ App is the ability to capture images during the scan data acquisition and visualise them in the Web Viewer as a panoramic image. The visualisation of the panoramic image facilitates the interpretation of the surface and is a valuable addition to the reflectance colouring calculated from the scan data.

The Monitor+ App, the latest development in RIEGL’s monitoring solutions, offers users flexible use of RIEGL’s terrestrial 3D laser scanners in all different monitoring scenarios. Monitoring projects can be interrupted and resumed at any time, or permanent monitoring can be carried out. The additional RIEGL V-Line CB23 communication box allows for seamless 24/7 monitoring and remote access to the scanner. All the familiar analysis functions of the already known monitoring apps, such as comparison with a design model or analysis of slope angles, can also be utilised in the Monitor+ App. Furthermore, the configuration wizard in RiSCAN PRO allows for the straightforward definition of complex monitoring schemes involving multiple areas and prisms with multiple schedules. The analysis processing is automatically carried out on the scanner and the results are displayed in a web viewer, which is accessible without the need for complex software. This solution enables surfaces to be monitored efficiently so that appropriate actions can be taken, while at the same time ensuring the safety of mining operations.

Subscribe to the blog for the latest updates