Innotech Marine emerged from the collective expertise and experience of its sister company, Innotech Engineering. Innotech Engineering has established itself as a successful engineering contract business with a proven track record of developing forward-looking technology stacks, IoT solutions, and enterprise architecture for some of the world’s most well-known companies.

Original Source - Nexa3D

The Customer

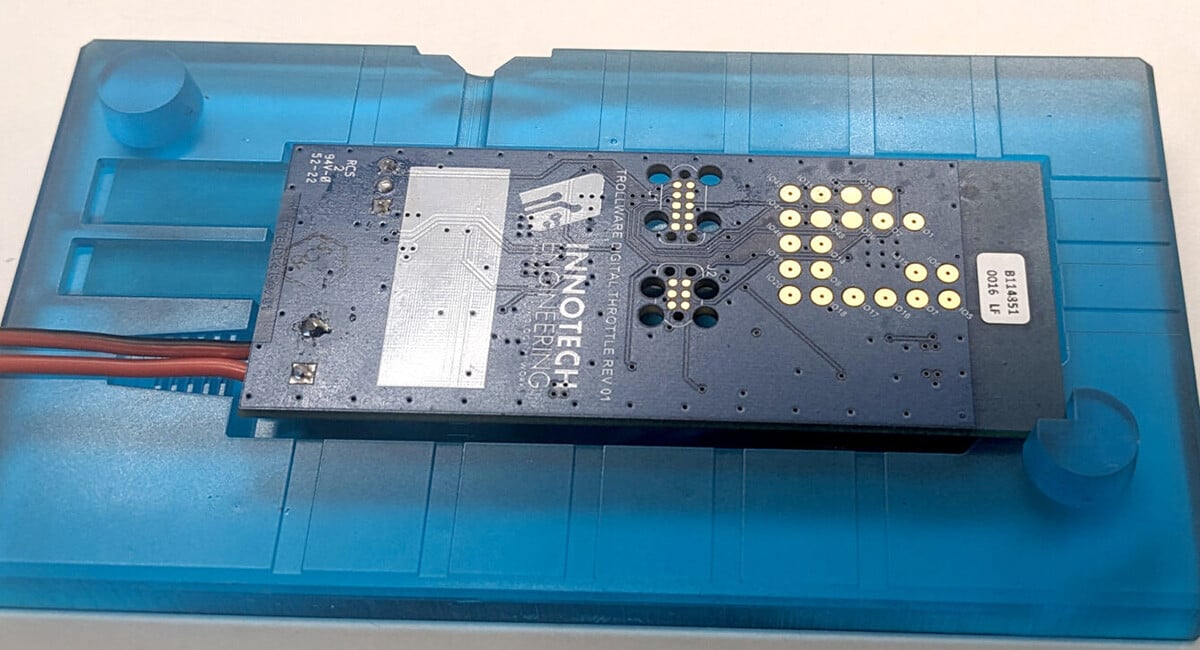

Leveraging this rich heritage, Innotech Marine was created to focus specifically on advanced IoT solutions for the sport fishing industry. Faced with the challenge of needing durable, waterproof, and saltwater-resistant enclosures for its PCB electronic components, Innotech Marine set out to create prototypes that met high standards for durability while looking and feeling like final production models.

INDUSTRY

Marine Electronics

PRODUCTS

XiP Desktop 3D Printer

xMOLD 3D printed tooling resin

APPLICATION

Waterproof Enclosures for IoT Electronic Components

ADVANTAGES

- Reduced costs through advanced 3D printing and molding technologies.

- Quicker prototyping enabled rapid presentation of production-like models.

- Created prototypes that closely mimic final products in durability and performance.

- Improved PCB design for better overmolding and durability in marine environments.

The Challenge

Developing Durable, Professional-Grade Enclosures Without Traditional Tooling and Production Costs

The key challenge was to develop durable, professional-grade enclosures for prototype electronics without the time and financial investment traditionally required for tooling and production. It also became clear that overmolding would be the ideal solution to ensure maximum protection for these components to avoid exposure to corrosive saltwater. Overmolding, a process that involves molding a material over another to create a unified part, is notoriously difficult due to the complexities of material compatibility, adhesion, and the need for precise mold design. Innotech Marine needed a solution that would allow them to overcome these challenges and create high-quality, production-like prototypes quickly and cost-effectively.

Overmolding required careful consideration of materials, especially given the harsh marine environment in which these products would operate. Ensuring that the overmolded material adhered properly to the underlying electronics without compromising their functionality was critical. Additionally, the process needed to be flexible enough to allow for rapid prototyping iterations, as the product design evolved.

“The ability to rapidly iterate and produce prototypes that felt like production models was a game-changer for us. It gave us the confidence to move forward with designs that we knew would work in the real world.” – Tyson Colby, Innotech Marine’s Principal Engineer and CEO

The Solution

Cost-Effective, Durable Prototypes with Advanced 3D Printing and Injection Molding

Innotech Marine turned to Nexa3D’s advanced manufacturing solutions to address these challenges. They utilized the XiP desktop 3D printer and Freeform Injection Molding technology, along with Henkel’s TECHNOMELT®, to achieve the necessary durability and resistance for their electronics enclosures.

XiP Printer Capabilities:

The XiP printer is known for its high-speed printing capabilities and ability to produce detailed and complex parts with precision. Its compatibility with a wide range of materials allows for the creation of prototypes that closely mimic final production parts. The printer’s speed and accuracy enabled Innotech Marine to rapidly iterate on their mold designs, testing different geometries and materials to find the optimal solution.

Freeform Injection Molding:

Freeform Injection Molding is a process that combines the flexibility of 3D printing with the durability and wide array of materials associated with traditional injection molding. It allows for the creation of complex parts without the need for expensive and time-consuming tooling. With Nexa3D’s xMOLD resin, you can print FIM tools in minutes and hours. This process was particularly beneficial for Innotech Marine, as it enabled them to create prototypes that closely matched the final product in both appearance and performance. The ability to use production-grade materials in the molding process ensured that the prototypes were not only functional but also ready for real-world testing.

Implementation

Rapid Prototyping:

Using the XiP printer, Innotech Marine was able to quickly iterate on the design of their enclosures. The printer’s high resolution and ability to work with a variety of materials were crucial for experimenting with different design concepts and overmolding techniques.

Overmolding Process:

The team employed Freeform Injection Molding tools along with a manual press to inject TECHNOMELT® over the PCBs, creating durable enclosures. Overmolding, while challenging, was made more manageable with the precision and control provided by the XiP printer and the flexibility of Freeform Injection Molding. The process involved carefully balancing the material flow and ensuring that the mold design facilitated proper adhesion and coverage of the underlying electronics.

Learning and Adaptation:

Throughout the process, Innotech Marine gained valuable insights into mold design, material properties, and the intricacies of overmolding. These lessons informed future product development, allowing the team to refine their designs for better manufacturability and performance in harsh environments.

“We learned so much about the nuances of mold design and material compatibility,” said Colby. “This experience not only improved our current project but will benefit our future developments as well.”

Results

Cost-Effective Development:

By leveraging Nexa3D’s Freeform Injection Molding and XiP 3D printer, Innotech Marine was able to avoid the high costs associated with traditional tooling and production methods. This approach enabled them to stretch their development budget while still producing high-quality prototypes.

Faster Time-to-Market:

The ability to quickly iterate on designs and produce prototypes allowed Innotech Marine to showcase their products at trade shows like the ICAST show, giving them the opportunity to present production-like prototypes well before the final product was ready. The speed and efficiency of the XiP printer were instrumental in meeting tight deadlines and ensuring that the prototypes were ready for real-world feedback.

Enhanced Product Design:

The process revealed new insights into product design, particularly in how to optimize the geometry of PCBs for better overmolding. This knowledge will be used to improve future products, making them easier to produce and more durable in the field.

Innotech Marine’s experience with Nexa3D’s XiP 3D printer and Freeform Injection Molding technology demonstrates how innovative manufacturing approaches can enable small businesses to compete in demanding industries. By combining advanced 3D printing with overmolding techniques, Innotech Marine has been able to bring high-quality, durable prototypes to market faster and more cost-effectively than would have been possible with traditional methods. This highlights the potential of cutting-edge technology to transform product development processes, making complex and challenging projects more accessible and achievable for businesses of all sizes.