Some of the fastest-changing technology in the world can be found at the frontlines of military conflicts across the world. Armed forces need to stay at the cutting edge of technology to ensure military readiness and security, but that creates challenging standards for contractors who need to stay apace. Unmanned aerial vehicles (UAVs), or drones, are perhaps the best example of hardware technology that needs to iterate almost constantly to match the changing military landscape.

Original Source - Formlabs

Boresight, an Australian drone manufacturer, sets itself apart in a crowded industry by delivering high-quality, reliable, target drones for extremely low costs, as well as more technically advanced tactical drones commissioned by the Australian Strategic Capability Accelerator (ASCA) program.

We spoke with Justin Olde, Boresight’s CEO and an ex-Army Tank Commander, to learn how the Fuse Series ecosystem and Formlabs’ Australian partner Thinglab have helped Boresight scale their design and manufacturing process to create a new product line in a competitive market.

“When we transitioned to more technically advanced drones, we wanted to keep the flexibility of scalable 3D printing, but we needed a more sophisticated material. It needed to be stronger, engineering-grade, and that’s what the Fuse allowed us to do.” - Justin Olde, Boresight CEO

Expendable Drones, Indispensable Experience

As drones have become integral to every facet of military operations, from surveillance and scouting to communications systems and tactical missions, it has become imperative to train armed forces to defend against them as well as deploy them.

Boresight set itself apart by cornering the market on expendable drones used in anti-aircraft training exercises. The Australian military needed a domestically manufactured solution to train their armed forces, and they needed it to be affordable, reliable, and easy to deploy across different sections of the military. Traditional manufacturing, with the high costs of tooling and the long lead times, would make it too difficult for Boresight to iterate and deliver technologies as quickly as the military needed them.

“We built the entire company around 3D printing capability — the flexibility and the customization that 3D printing allows us. Our target drones are printed using FDM with PLA filament because they need to be as cost-effective as we can make it – they’re built to be destroyed,” says Justin. Because FDM 3D printing was so inexpensive, Boresight was able to create an extremely cost-effective manufacturing process that still delivered reliable, easy-to-use products.

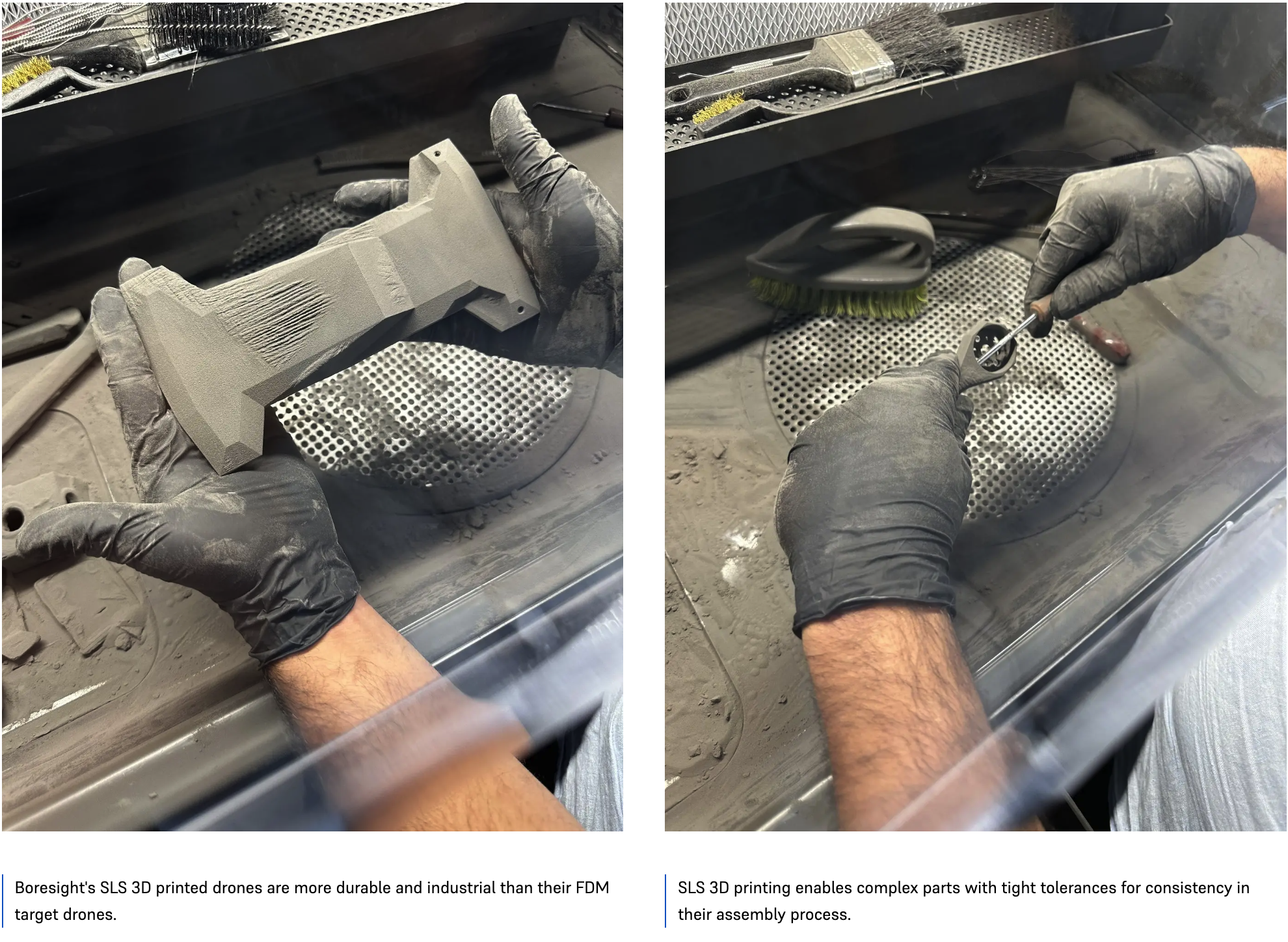

When Boresight was asked to expand from target drones (right) into mission-ready drones (left), they turned to SLS 3D printing for its end-use capabilities and agile manufacturing workflow.

When Boresight was asked to expand from target drones (right) into mission-ready drones (left), they turned to SLS 3D printing for its end-use capabilities and agile manufacturing workflow.

When a contract from ASCA came up for non-target drones that are more durable and industrial-grade, Boresight was able to easily secure funding — Boresight’s WEngineering team knew they could build high-quality drones for affordable prices, they just needed engineering-grade materials to do it.

“We got very, very good at making drones efficiently. As a consequence of that, it made us quite competitive in the accelerator program when they began looking for cost-effective, Australian-made performance drones. That’s the reason we started to look at the Fuse,” says Justin.

Proven Workflow, New Power

As Boresight began evaluating options for designing and manufacturing a more robust, high-performance drone, they needed a solution that maintained their low-cost, high-value operating model but also offered materials that were strong, lightweight, and rugged enough to be deployed in any type of environment.

“Probably the biggest contribution of the SLS technology is that we’re getting engineering-grade materials. We can make engineering decisions based on the thickness of the part’s features. Particularly with PLA on the FDM printers, you’re not able to get consistency, so you go thicker and heavier. With SLS you’re able to put that material into a finite engineering analysis program and determine how that feature will perform,” says Justin.

After evaluating other powder bed fusion 3D printers, Boresight Engineers weren’t convinced that a large, traditional industrial system was the answer. The high up-front costs wouldn’t be covered by the ASCA contract, and to achieve a fast ROI would mean their production would have to skyrocket overnight. They needed quality and reliability, without a price tag close to half a million dollars. “Value for money is a big one for us — the whole company is built on value for money solutions, and every dollar we spend has to be recovered down the line. The Fuse Series gives us that quality for money capability,” says Justin.

Completing the Ecosystem and Improving Efficiency

As soon as the facility was ready, the Boresight team added a Fuse Blast cleaning and polishing system as well as a second Fuse 1+ 30W printer. “Where we are now, with two printers running, we can just finish a build, throw it in the Blast, and get a better finish than we ever did, doing it by hand. In terms of production capacity and efficiency, it’s been a huge benefit to us,” says Justin.

As soon as the facility was ready, the Boresight team added a Fuse Blast cleaning and polishing system as well as a second Fuse 1+ 30W printer. “Where we are now, with two printers running, we can just finish a build, throw it in the Blast, and get a better finish than we ever did, doing it by hand. In terms of production capacity and efficiency, it’s been a huge benefit to us,” says Justin.

Manufacturing Boresight’s High-Performance Drone on the Fuse

The self-supporting nature of the SLS build chamber gives the Boresight design team the flexibility they need to pack parts densely. They can nest parts for the chassis, arms, mounts, battery compartments, and camera housings within each other within a Fuse build. Hitting a high pack density has the added benefit of driving down their cost per part, helping them maintain their lean manufacturing model. “Nearly everything on our drone is printed on the Fuse,” says Justin. Moving away from FDM technology gave the design team more freedom to create parts that were lightweight, yet strong and durable, even under harsh conditions.

The self-supporting nature of the SLS build chamber gives the Boresight design team the flexibility they need to pack parts densely. They can nest parts for the chassis, arms, mounts, battery compartments, and camera housings within each other within a Fuse build. Hitting a high pack density has the added benefit of driving down their cost per part, helping them maintain their lean manufacturing model. “Nearly everything on our drone is printed on the Fuse,” says Justin. Moving away from FDM technology gave the design team more freedom to create parts that were lightweight, yet strong and durable, even under harsh conditions.

“This drone is intended for military organizations, which aren’t known for treating things kindly. They need things to be simple, light, and strong, which are generally conflicting requirements. But by using the Fuse, we can do that.” - Justin Olde, Boresight CEO

Flexibility Enables a Future-Proofed Approach

In the drone industry, the only constant is change. To make sure that Boresight can weather the changing tides of a fast-paced industry, Justin has gone all in on 3D printing. “The problem with traditional technologies like injection molding or vacuum molding is that they take away your flexibility. With the style and work that Boresight is doing, we need that ability to respond to requests for small variations at any time. 3D printing and the Fuse Series give us those options. We can change constantly — all we need to do is wake up one morning and adjust a design, then let the printers do the rest,” says Justin.

On-demand manufacturing with SLS helps Boresight be nimble and responsive to changes in the industry — from one military unit needing a different-sized camera to a rotor blade supplier changing the location of the attachment fixture. Changes that might cost a traditional manufacturer hundreds of thousands of dollars in obsolete tooling only require 10 minutes of design reworking before a new solution gets printed. “We’d need to be churning out awfully significant volumes for an injection molding scenario to make sense. The tooling for parts like the chassis could be around $100,000, and if the payload changes after a year, I haven’t gotten nearly the ROI I need on it,” says Justin.

With a lower barrier to entry than traditional manufacturing options or large-format powder bed fusion printers, the Fuse lets Boresight move incrementally. They’ve been able to match their output to their demand through strict adherence to what sets them apart — a viciously lean manufacturing model. Scaling with the Fuse Series SLS ecosystem keeps them all-in on 3D printing while leveling up their capabilities for stronger, end-use drones.

"The Fuse technology gives us the power to change. As we develop and scale up our production, we’ll be scaling up with the Fuse as well." - Justin Olde, Boresight CEO