FormLabs | Dental Maximum Throughput

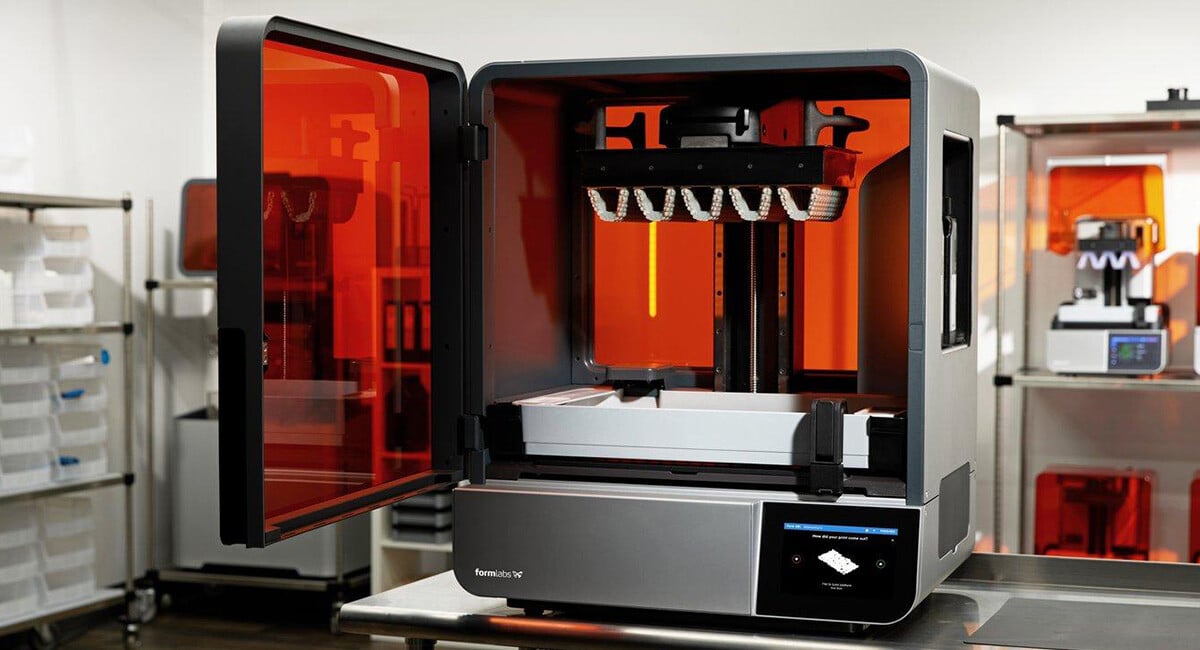

Introducing Form 4BL, the fastest large-format dental SLA printer for printing dental models and biocompatible parts. Whether you need high-throughput model production or rapid manufacturing of biocompatible appliances, Form 4BL offers the blazing speed, accuracy, reliability, and ease of use of Form 4B with a 4.6x larger build volume.

Estimates based on orthodontic models printed with Fast Model Resin at 160 μm.

Estimates based on orthodontic models printed with Fast Model Resin at 160 μm.

Significant technological updates mean Form 4BL prints 2-4x faster than Form 3BL, unlocking the ability to print more than 120 orthodontic models per hour.1 Plus, with a 2.7x larger build surface than Form 4B, print multiple print batches per day with fewer user interactions to maximize efficiency.

Production-Ready Throughput

“We are currently using the Form 4BL for all our model production, and the Form 4Bs for biocompatible applications. With the Form 4BL's build platform, which is around three times larger, we can now produce three times more models with a single user intervention.” - Stephan Kreimer, MDT, Kreimer Dentallabor

Form 4BL is built on the same technology as Form 4B, enabling blazing speed without compromising on accuracy. Quicker heating and 5-10x faster resin dispensing mean prints start sooner. Once printing starts, achieve 10-80 mm/h print speeds, depending on the material.

On Form 4BL, print 32+ models in Fast Model Resin at 160 μm in 15 minutes, for a total throughput of more than 100 models per hour. While print speeds vary depending on material and layer height, print time will be similar whether you’re printing one part or many, so case volume doesn’t have to impact how you plan your printing schedule.

The ~1.8x increased throughput of Form 4BL comes with three times fewer user interactions than Form 4B: printing with Form 4B’s smaller build platform requires removal and reinsertion three times to reach the same output as Form 4BL. Produce more models in less time while freeing up workers for higher-value tasks — all while achieving the same high precision and accuracy.

Increasing Throughput at Aurora Dental Lab

“Everything is easy to use. We're enjoying the benefits of the large format, and the simple-to-use process.” - Rich Heilweil, Rapid Prototyping Team Lead, Aurora DTC

At Aurora DTC, Form 4BL was the first large-format dental 3D printer to be added to the lab’s fleet and was met with excitement. Rich Heilweil, Rapid Prototyping Team Lead, says, “It’s unique, something different for us. It’s very productive to be able to nest so many models at once and print in one run. It’s a big advantage for us.”

Printing many applications at high volumes, Aurora likes to dedicate each printer to a specific resin and application. In the case of Form 4BL, Precision Model Resin is being used to print highly accurate implant models and dies at 50 μm layer height.

Milos Markovic, Director of Cad-Cam and Implantology at Aurora DTC, says that accuracy and speed are key considerations when selecting a 3D printer. He was impressed by the finish and quality of Precision Model Resin, and Form 4BL offers not just blazing speeds, but the ability to meet Aurora's high-throughput needs.

“We’re able to get two, high-throughput prints completed in a day, with only two post-processing periods as opposed to four. This frees me up to do other tasks that need to be done in my lab, so I have much more availability.” - Rich Heilweil, Rapid Prototyping Team Lead, Aurora DTC

Rather than printing multiple print runs on Form 4B, each requiring a user to remove the build platform and post-process the prints, Form 4BL allows Heilweil to batch prints, so he can print the same number of models in fewer builds. With fewer print runs in a day comes fewer pauses in other tasks to post-process, leading to more time for higher-value tasks — all while maintaining or increasing the volume of model per day.

Models are the highest volume application at Aurora, but Markovic sees the potential for biocompatible printing in the future. As dentists continue to adopt intraoral scanning at increasing rates, the demand for digital dentures is increasing. Markovic can see a future in which large-format 3D printing of biocompatible resins — such as those for denture teeth and bases — would revolutionize production.

Redesigned for Reliable Production

Six intelligent control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside Form 4BL while remote monitoring enables users to monitor and manage prints from anywhere.

Six intelligent control systems precisely measure and maintain the temperature, resin level, print forces, and print status inside Form 4BL while remote monitoring enables users to monitor and manage prints from anywhere.

“As a dental lab, reliability is essential for us to deliver our products on time. With Formlabs’ ecosystem, our 3D print success rate is now close to 100%. Compared to other 3D printers we’ve used in the past, Formlabs shows much higher performance and reliability.” - Stephan Kreimer, MDT, Kreimer Dentallabor

Dental professionals need to be able to reliably meet deadlines with high-quality products. Knowing a print batch will be successful keeps your operation working smoothly and efficiently. Form 4BL solves for the pain points of users and is faster, more reliable, and easier to operate and maintain than our previous large-format SLA 3D printers.

“Compared to some of the more expensive printers we use in our lab, the Form 4BL stands out for its efficiency. We can fit two to three times more models on its build platform, all with a similar print duration and exceptional reliability and accuracy. The result? Our throughput has doubled, even tripled, which has been a game-changer for us!" - Milos Markovic, Director of Cad-Cam and Implantology, Aurora DTC

Inside the printer, six intelligent control systems precisely measure and maintain the temperature, resin level, print forces, and print status. Plus, with remote monitoring you can monitor your prints and manage your printers from anywhere with an integrated camera, preventative maintenance reminders, and our free Dashboard software.

Reliability starts at the factory with a 60-point calibration and quality control inspection, so Form 4BL arrives ready to print. We know that downtime costs your business, so we’ve re-engineered our consumables for years of use. Resin Tanks for Form 4BL are estimated to last 75,000+ layers, and the Light Processing Unit 4L (LPU 4L) for 600k - 1.9M layers. When required, the LPU 4L is easy to replace, so Form 4BL can be up and running without delays.

Easy Delegation With Intuitive Workflows Anyone Can Learn:

Form 4BL at Kreimer Dentallabor

"The entire ecosystem is crucial if you want to scale your business. For example, with most other 3D printers, you have to manually pour in the material and there’s no wiper, so a lot of tasks must be done by hand. Formlabs, on the other hand, is much more user-friendly and easier to delegate to the team." - Stephan Kreimer, MDT, Kreimer Dentallabor

At Kreimer Dentallabor, Stephan Kreimer, MDT, has found that adding a Form 4BL to his printer fleet has increased productivity and efficiency. A full-service dental laboratory, over 80 percent of Kreimer Dentallabor customers are digital. This means the lab produces high quantities of dental models, around 30-50 a day.

Managing this quantity of models plus manufacturing appliances with their team of 12 would be impossible without reliable, high-throughput 3D printing. Additionally, high labor costs and limited access to skilled technicians mean efficiency and cost-savings are top of mind.

While the team loved the speed and accuracy of Form 4B, the quick print batches necessitated frequent movement from a task to the printer and back again. With the addition of Form 4BL, these interactions were reduced by more than 50%. Now, Kreimer Dentallabor can batch models together, saving time and reducing the potential for distractions.

“You spend much less labor time on cleaning, washing, and curing because you can process three times more models at once. The time needed for post-processing 30 models is almost the same as for 10 models,” says Kreimer.

Kreimer’s team found that learning to print on Form 4BL was just as intuitive as earlier Form Series printers, minimizing the time it takes to onboard team members, whether they’re new to the printer or new to the lab. As Kreimer says, “everyone can do it in 15 minutes.”

Learn more about how Form 4B and Form 4BL drive efficiency at Kreimer Dentallabor in our case study.Precise and Accurate Prints for Appliances That Fit, Every Time

“I was very happy with the print quality on the Form 4B, and it's the same on the Form 4BL. We can use Form 4BL for our products because we need to trust our dental models and the print quality is one of the best on the market.” - Stephan Kreimer, MDT, Kreimer Dentallabor

Reliably producing precise, accurate parts with a perfect fit is top of mind for dental professionals — whether they’re restorative models with removable dies and implant analogs, or final restorations that need to look life-like and adapt perfectly. Parts printed on Form 4BL have ±0.15% XY dimensional tolerances across the build platform, for parts that match your design parameters every time.

Form 4BL features the same technological advancements as Form 4B. Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for subpixel resolution and lower peel forces allow you to achieve the sharpest details and smooth surfaces.

Material Flexibility: Biocompatible Resins and Open Material Mode

Formlabs’ dental material library of 15+ materials includes seven biocompatible resins. Biocompatible resins can be printed on Formlabs biocompatible printers, including Form 4BL.3 Formlabs biocompatible resins are developed and manufactured within our robust Quality Management System that is ISO 13485 and EU MDR certified. Scale occlusal splint production with Dental LT Comfort Resin or Dental LT Clear Resin, or maximize surgical guide production to meet the needs of your customers.

Flexible occlusal splints printed with Dental LT Comfort Resin are easily polished to high optical transparency, and offer enhanced comfort and durability that boosts patient adoption and compliance.

Flexible occlusal splints printed with Dental LT Comfort Resin are easily polished to high optical transparency, and offer enhanced comfort and durability that boosts patient adoption and compliance.

All Formlabs resins are validated on the printer, with optimization engineers putting hundreds of printed parts to the test, dialing in validated print settings to empower reliable printing right out of the box. Print highly precise and accurate restorative models with Precision Model Resin, or leverage the speed of Fast Model Resin to produce 120 orthodontic models per hour.

Users seeking more flexibility can take advantage of Formlabs' open ecosystem on Form 4BL. This includes the Print Settings Editor, which enables fine-tuning of print parameters to meet specific needs, and the Open Material Mode (OMM), allowing for broader material compatibility.

OMM empowers expert users to leverage the speed, accuracy, and heating capabilities of Form 4BL to print with any third-party 405 nm photopolymer resin.4 To learn if OMM is a good match for your business goals, talk to a dental sales representative.

The Fastest Large-Format Dental 3D Printer

“If you have one application that’s way bigger than all other applications — often dental models — it makes sense to add a Form 4BL to be able to have one printer for high volume production.” - Stephan Kreimer, MDT, Kreimer Dentallabor

At Kreimer Dentallabor Form 4BL is used to efficiently print highly-accurate restorative models in Precision Model Resin.

At Kreimer Dentallabor Form 4BL is used to efficiently print highly-accurate restorative models in Precision Model Resin.

Cost efficiency is top of mind at dental and orthodontic labs. Form 4BL decreases touchpoints, providing the speed and quality you’ve come to love with Form 4B, while saving technician time. Increase your throughput while providing appliances that fit every time with Form 4BL.

Buy now to start ramping up your production or contact sales to discuss the optimal printer fleet for your lab.