Formlabs Dental is committed to providing best-in-class solutions for dental 3D printing, responding to the needs of dental professionals to provide comprehensive solutions that make dentistry easier. Our latest releases include the addition of BEGO™ VarseoSmile® TriniQ® Resin to our dental materials library, Open Material Mode on Form 4B for the printing of any 405 nm resin on the market as well as custom resins, and Formlabs Resin Washing Solution, a non-flammable, low-odor alternative to washing parts with isopropyl alcohol.

Original Source - FormLabs

BEGO™ VarseoSmile® TriniQ® Resin

BEGO™ VarseoSmile® TriniQ® Resin is now available for Formlabs’ Form 4B 3D printer. With this release, Form 4B users can now produce permanent single-units, implant crowns (Ti-bases) and permanent bridges up to three-units, enabling the production of durable and aesthetic same-day restorative parts.

“VarseoSmile TriniQ has shown good precision and consistency during my testing phase. The material’s processing workflow is straightforward and efficient, with no need for extensive post-processing. Additionally, the aesthetic quality of the final product is satisfactory, providing a lifelike appearance that meets the needs of modern prosthodontics.” - Dr. Michael Braian, DDS, CDT, PhD, Founder of the Swedish Organisation for Computer Aided Digital Dentistry (SWECADD)

3D print permanent bridges up to three-units with life-like aesthetics.

A Versatile Resin for the Production of Permanent Single Units & Bridges

BEGO™ TriniQ® Resin is the first resin indicated for permanent bridges (up to three-units), and can be used to print the following permanent single-units:

- Crowns

- Inlays

- Onlays

- Veneers

- Implant-supported crowns

This is the first time users can produce permanent implant crowns (Ti-bases) on the Formlabs ecosystem. Additionally, BEGO™ TriniQ® Resin can be used to print temporary restorations including single-units, bridges up to seven-units, and denture teeth.

Certified and Validated

As a Certified Material, BEGO™ TriniQ® Resin has been rigorously tested on the Formlabs ecosystem for a smooth, efficient workflow that enables users to spend more time on higher value tasks and less time troubleshooting prints. With Certified Materials, Formlabs Dental users can take advantage of automated resin dispensing and heating, free PreForm Dental print preparation software, and all the other benefits of the Formlabs Dental ecosystem.

Leverage the unmatched accuracy and blazing speed of Form 4B to print parts with over 95% surface accuracy within 50 µm of the CAD model, printed at either a 50 µm or 100 µm layer thickness, for a perfect fit every time.

BEGO™ did extensive testing on this material, including in-vitro studies to effectively demonstrate the performance of the material over time, and testing to confirm the fit on Ti-bases.

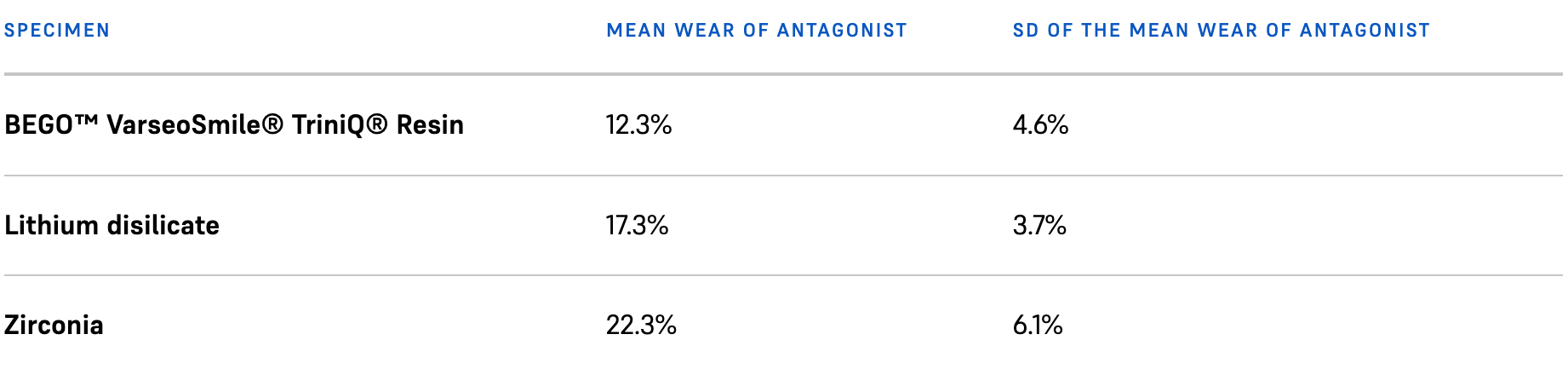

Tests showed that BEGO™ TriniQ® Resin is gentle on the antagonist, and had the lowest antagonist wear compared to lithium disilicate and to zirconia.

Table and graph from BEGO™’s compendium.

Table and graph from BEGO™’s compendium.

Additionally, parts printed with BEGO™ TriniQ® Resin can be repaired, relined, and are compatible with different cementation strategies.

The fracture load for three-unit bridges was also tested, with results indicating that even after the 10-year chewing simulation, breaking loads of three-unit bridges 3D printed with BEGO™ TriniQ® Resin are significantly greater than human biting forces of 720 N.

Graph from BEGO™’s compendium.

Graph from BEGO™’s compendium.

To learn more about the testing results of this certified material, download BEGO™’s extensive compendium including:

- Results of a 10-year chewing simulation

- Radiopacity investigation

- Wear behavior

- Bond strength

- Biocompatibility testing

- Case documentation of bridge restoration

- Preparation guidelines

Streamlined Workflow

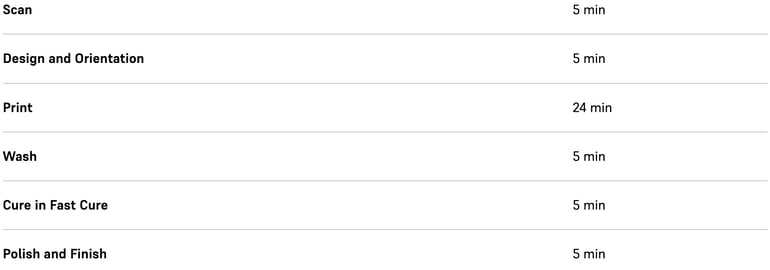

Validation on the Formlabs ecosystem means BEGO™ TriniQ® Resin users can take advantage of the blazing speed and unmatched accuracy of Form 4B, enabling the production of a single crown from scan to polished part in less than 50 minutes.

Production of a Single Crown

A single crown can be produced from scan to print in less than 50 minutes on Form 4B with BEGO™ TriniQ® Resin — all without sandblasting.

A single crown can be produced from scan to print in less than 50 minutes on Form 4B with BEGO™ TriniQ® Resin — all without sandblasting.

BEGO™ TriniQ® Resin must be printed on Form 4B with Build Platform Flex, which features a stainless steel print surface and patented quick-release technology, at either 50 µm or 100 µm layer height. Parts printed with BEGO™ TriniQ® Resin do not require sandblasting, for excellent polishability that ensures highly aesthetic appliances.

Create precisely fitting permanent and temporary single-unit restorations or bridges with optimal marginal adaptation, polishability, and longevity — all within an accessible and streamlined workflow that fits your production.

Restorative Dentistry With BEGO™ and Formlabs

After extensive validation and testing, Formlabs Dental users can now leverage the enhanced mechanical properties and aesthetics of BEGO™ TriniQ® Resin to 3D print permanent restorative parts on Form 4B — all at lower costs than previous permanent restorative solutions. A single cartridge of BEGO™ TriniQ® Resin can be used to print up to 300 crowns, offering a competitive solution for 3D printing permanent restorations and bridges.

Buy BEGO™ TriniQ® Resin to start printing permanent restorations and bridges on Form 4B, or contact a dental specialist to learn how Formlabs Dental can help you meet your business goals.

Certified Materials & Open Material Mode for Form 4B

BEGO™ VarseoSmile® TriniQ® Resin is a Certified Material, a resin developed and manufactured by a third-party and certified for use on Form 4B. With Certified Materials, users can be assured of reliability and user experience when printing, offering peace of mind.

Open Material Mode unlocks the ability to use any 405 nm photopolymer resin on Form Series Printers, empowering expert users and researchers to print with any material on the market as well as custom resins.

Formlabs Resin Washing Solution

Formlabs Resin Washing Solution is a next-generation cleaning solution that is ideal for washing dental models.

Formlabs Resin Washing Solution is a next-generation cleaning solution that is ideal for washing dental models.

“Formlabs Resin Washing Solution is key in my 3D printing workflow. It washes my models completely and I can go much longer without worrying about replacing solvent. It doesn't have a strong smell and isn't a flammability risk, which I appreciate for my small work space.” - Kristine Paxon, Lab Technician, Beam Orthodontics

Formlabs Resin Washing Solution is the next-generation cleaning solution for the washing of non-biocompatible resin 3D printed parts, including the following model resins:

- Precision Model Resin

- Fast Model Resin

- Grey Resin

This non-flammable, low-odor washing solution cleans as well as isopropyl alcohol (IPA), but can dissolve twice as much resin before becoming saturated, for a lower cost per wash and less time spent changing washes, for cost-efficient production of models. Whether you buy directly from Formlabs or our partners, you can now get your resins and washing solution all in one place, for streamlined sourcing.