The mining industry in South Africa contributes R350 billion to the economy annually, with an estimated R35 trillion of resources left to mine. Mining companies in Africa and across the globe are continually reviewing ways of working and best practices for mining safely, efficiently, and sustainably. Research and development play a big role in these changes, with early adopters of new technologies benefitting the most.

Original Source - FARO

The Customer

Barberton Mines has been operational for 130 years and is in Mpumalanga, South Africa. Consisting of several mines, including Fairview, Sheba, and New Consort, they extract approximately 80,000 oz of gold annually. In recent years, Barberton has evaluated new technologies to make its mining processes faster, safer, and more cost-effective.

One of the ways in which Barberton Mines invested in new technologies, was by investigating opportunities to improve their survey workflows. They adopted static-based LiDAR solutions to produce accurate 3D models and became one of the first users of mobile SLAM (Simultaneous Localization and Mapping) solutions in 2014.

The Challenge

While static-based scanners are highly accurate, the survey team at Barberton Mines needed a quick and versatile solution for the variety of mining methods employed on the different mines and ore bodies. The goal was simple — capture data daily, accurately, and safely for ongoing analysis of the mining production. In addition, they needed a solution that could easily handle the rugged terrain and environment that mines are so often known for.

Barberton Mines chose to reassess their underground mapping technology to improve the speed and accuracy of their survey operations and increase productivity in the mines.

The mobile mapping solution is lightweight and accurate, making it the perfect tool for mapping. The survey team can complete scans of the mines in half the time compared to traditional surveying, and the process is repeatable. These capabilities have contributed to Barberton Mines streamlining their

workflows, long-term cost savings, and greater returns

on investment.

The scanner only requires one person on-site to capture data. Furthermore, it doesn’t require professional training to use the equipment so operators can capture data in parts of the mine that surveyors cannot access for safety reasons. This casts a virtual eye on areas of the mine previously unseen by the surveyors and creates an opportunity to review old tunnels.

Finally, the scanner’s intuitive ease-of-use benefits new employees and the mine in general. It takes less than an hour to learn how to use the equipment and to process the final point cloud data, allowing surveyors more time to analyze the data and find ways to improve efficiencies in the mining process.

The Solution

Having originally invested in mobile scanners for underground mapping, Barberton Mines have since adopted the technology for other applications, further increasing their return on investment. The scanners are now operating across three key aspects of Barberton’s mining process.

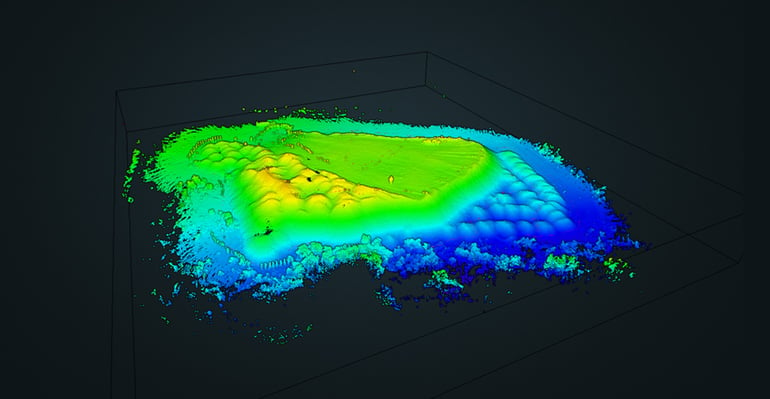

Production Progress Mapping

The original and most common use for scanning is Production Progress Mapping. Barberton completes daily scans of the mines, bringing the data back for regular analysis of production progress mapping.

The scanned areas are approximately 300m3 and using SLAM technology, they can scan large areas in about 10-15 minutes. The scanners are handheld, so production in the mines is not compromised. Surveyors begin their scans in a safe area, proceed to the mining faces, and loop back to the safe area while capturing the data needed – a completely repeatable and efficient process.

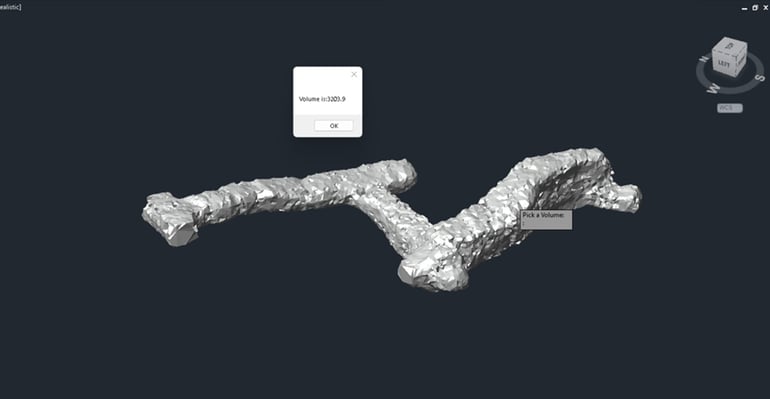

Stockpile Measurements

Barberton Mines has 5-6 stockpiles that makeup 4000 cubic tons of material. They frequently measure the volume of these stockpiles, to ensure they have accurate and up-to-date information of the resources.

Simply walking around the stockpiles with a scanner and importing the data into 3rd party software, provides the survey team with all the information they need to produce required reports.

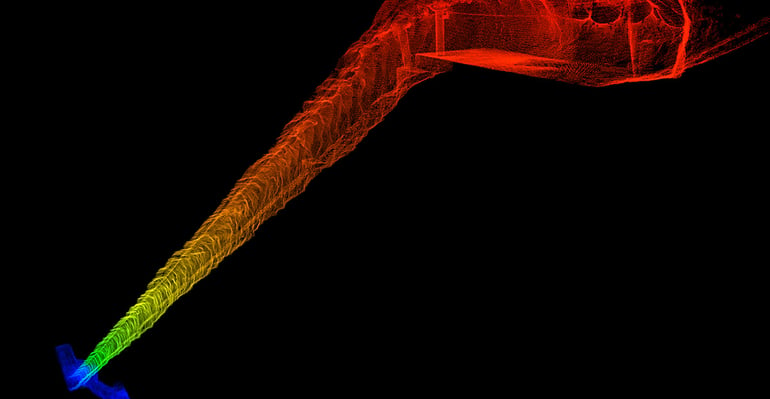

Health and Safety

One example of where scanning has improved health and safety is the mapping of transport shafts. To comply with safety regulations, surveyors frequently scan the shafts to look for rock movement or deformation that might require further investigation.

They found that scanning tunnels from the chairlift with a handheld scanner was quicker than previously used conventional methods, like Terrestrial Laser Scanning (TLS) or by hand. Handheld scanners only require the operator to take the chairlift down and back up again with the scanner.

The scanners are frequently used in these applications and their robust nature means they have never needed repair or maintenance.

The Future

Fast, efficient, and accurate data capture from mobile LiDAR scanners has proven to be a significant benefit for Barberton Mines. The repeatability of the scans has provided an excellent return on investment and the durability has meant that despite usage in challenging environments, the scanners have endured. The speed of data capture has led to safer work practices for the surveyors and the walk-and- scan method has resulted in no disruption to daily mining operations.

With the scanner’s versatility, the survey team is still finding new applications where the technology can be utilized in the mining environment.