In a region where the surveying industry is still largely dominated by 2D methods, Hayashi Survey Technical Consultant Inc. is leading the charge in introducing 3D technology to the surveying and geological mapping sector. Established in December 2003, Hayashi Surveying has grown to become a respected name in Japan, serving national, prefectural, and municipal governments in and around the Osaka Prefecture.

Original Source - FARO Technologies

Their expertise lies in preparing detailed documents for construction design, specifically in the realm of surveying and geological surveying for infrastructure projects. With a dedicated team of 15 employees, the company is proving that embracing modern technology can vastly improve both efficiency and quality in an otherwise traditional field.

Surveying in Japan, particularly for infrastructure projects such as road construction, often relies on long-established methods. While effective, these methods come with notable limitations. GPS-based point surveying, for instance, can be fast but lacks the richness of a point cloud, often leading to potential oversights. Similarly, total stations can capture accurate data, but struggle with speed and versatility. These limitations can result in time-consuming work, requiring multiple scans in difficult-to-reach locations.

For Hayashi Surveying, the adoption of GNSS technology had already paved the way for 3D scanning. By directly capturing points rather than relying on angles and distances from a total station, they were able to see the potential of moving beyond traditional 2D methods. However, even with GNSS and TLS, there remained gaps in coverage and efficiency — especially in rugged terrains and obstructed areas.

“TLS works well in urban areas, but we still need more flexibility in forests or narrow spaces,” said Tatsuo Hayashi, President of Hayashi Surveying. “And Orbis is exactly what we wish we had before now.”

In May 2024, Hayashi Surveying introduced the FARO Orbis Mobile Scanner to complement their existing tools. The decision to adopt the Orbis was driven by the need to overcome some of the inherent challenges of traditional surveying equipment. According to Hayashi, “Before Orbis, we had to scan 30 to 40 locations with our TLS, and even then, we struggled in tight spaces.”

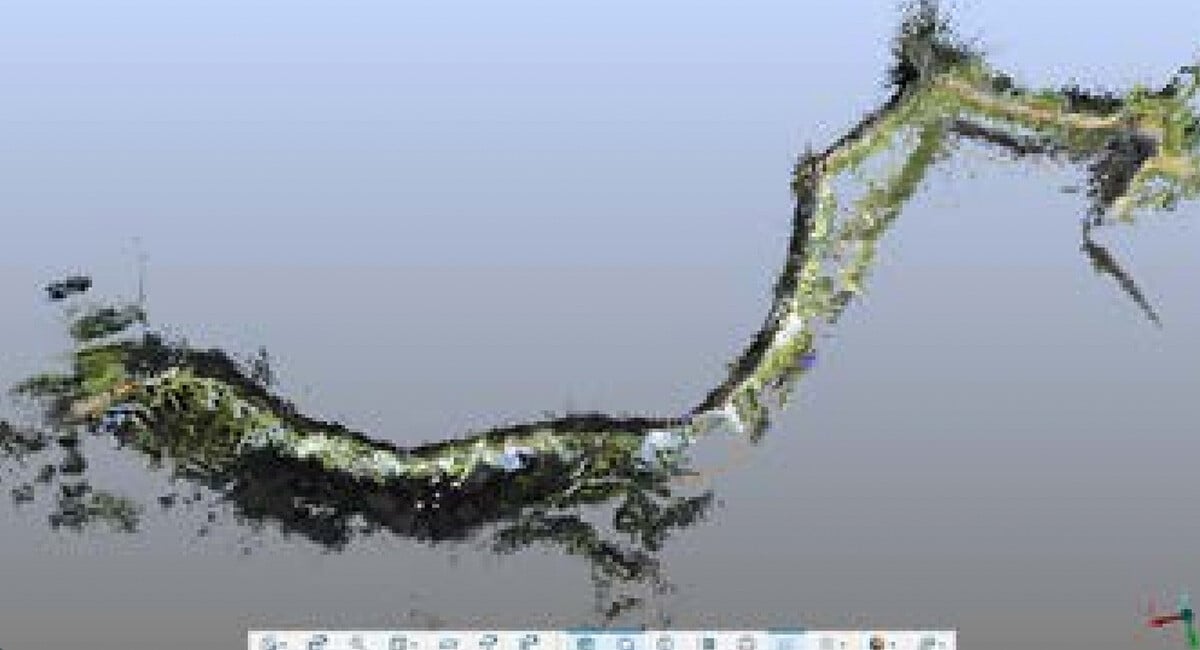

The Orbis Mobile Scanner’s ability to function without a direct GPS connection in difficult environments — such as forests or interior spaces — has been particularly beneficial. This feature enables the company to capture data in places where terrestrial scanners and drones simply cannot reach. “With Orbis, we can now scan where other tools fall short,” said Hayashi. “In forests, the GPS doesn’t always work, but with Orbis, we can capture the data without any issues. It’s a game-changer for us.”

“We’ve gone from needing three or more people on-site to just two. This saves on labor costs and allows us to manage more projects with fewer resources. Last year, we doubled our sales while keeping the same size team. The efficiency improvements thanks to FARO have been huge.” Tatsuo Hayashi - President of Hayashi Surveying

Since integrating the Orbis into their workflow, Hayashi Surveying has seen significant improvements in both the speed and quality of their surveys. One of the most notable benefits has been the reduction in on-site work time. Tasks that would traditionally take two full days can now be completed in half a day or even less — sometimes as little as one-eighth of the time.

“We’ve reduced our on-site work from two days to half a day, sometimes even less,” Hayashi said. “It’s not just about speed, it’s about efficiency — getting the data we need in less time and with fewer errors.”

Moreover, the streamlined process has enabled Hayashi Surveying to cut down on the number of workers needed for each project. Where three or more staff members were previously required, now just two can efficiently manage the task. “We’ve gone from needing three or more people on-site to just two,” Hayashi explained. “This not only saves on labor costs but also allows us to manage more projects with fewer resources.”

The shift to 3D technology has brought about other long-term benefits as well. By using the Orbis in conjunction with their existing GNSS and TLS tools, Hayashi Surveying has created a workflow that maximizes the strengths of each device. The TLS is still used in urban areas where its detailed data capture is essential, while the Orbis is employed in more difficult-to-reach locations, such as forests or mountainous terrains.

This efficient use of 3D scanning has significantly improved the company’s ability to handle a wider range of projects. The ability to generate detailed 3D point clouds has also led to improved accuracy and fewer instances of rework, as compared to traditional methods. As Hayashi notes, “With the Orbis, we don’t miss data like we used to with other tools. It helps us avoid rework and make sure we get the full picture the first time.”

Perhaps the most significant impact has been the ability to take on more work without increasing staff. The efficiency gains brought about by 3D scanning have allowed Hayashi Surveying to double its sales compared to the previous year, all while maintaining the same core team. This shift in productivity is a testament to the power of modern surveying technology in transforming how businesses can operate in an increasingly competitive landscape. “We’ve been able to double our sales while keeping the same team size. The efficiency improvements have been huge,” Hayashi said.

Looking ahead, Hayashi Surveying aims to continue leveraging 3D technology to further improve their operations, plus push for wider adoption of 3D tech in the region, where local governments have been preventing the use of new technology in the name of protecting local contractors.

The goal for Hayashi Surveying is to shift the balance of their work from on-site to in-house tasks, optimizing the efficiency of fieldwork even further. With the Orbis scanner, they plan to take on more complex projects while maintaining — or even improving — their efficiency.

“We’ve already shifted our work ratio from seven days on-site and three in-house to three days on-site and seven in-house,” Hayashi said. “We’re also delivering 3D drawings alongside our 2D deliverables, to show our clients the power of 3D versus 2D. We want to continue spreading the word about the benefits of working in 3D.”

Hayashi believes that the future of surveying lies in 3D and that the companies that do not evolve with this change will be weeded out of the market. “3D is going to be the standard in the future, but the industry in our region needs to start adapting now,” Hayashi said. “Investing in technology today is how we’ll survive and thrive in the future.”

Hayashi Surveying’s journey towards 3D surveying demonstrates the profound impact that technology can have on traditional industries, and also that long-established companies can embrace change and remain competitive. By adopting innovative solutions like the FARO Orbis Mobile Scanner, Hayashi Surveying has not only enhanced the quality and efficiency of their work but also positioned themselves as leaders in the future of surveying. As the industry continues to evolve, Hayashi Surveying’s success serves as a valuable example of how the adoption of 3D technology can drive operational and f inancial growth in an increasingly demanding field.

Subscribe to the blog for the latest updates