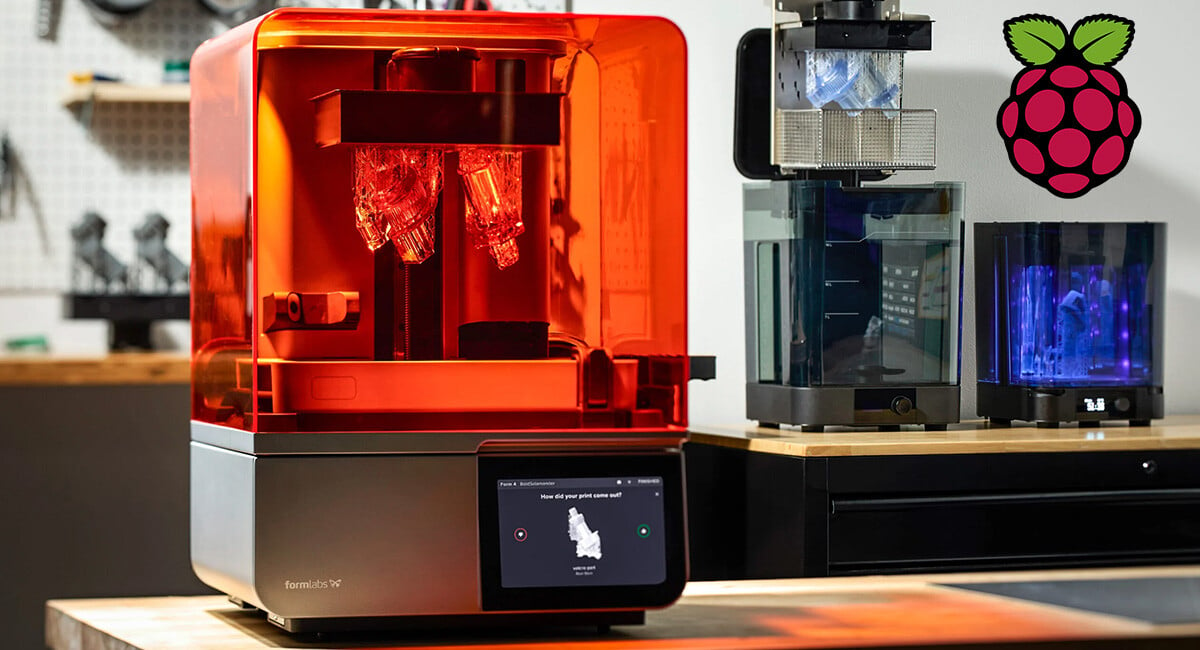

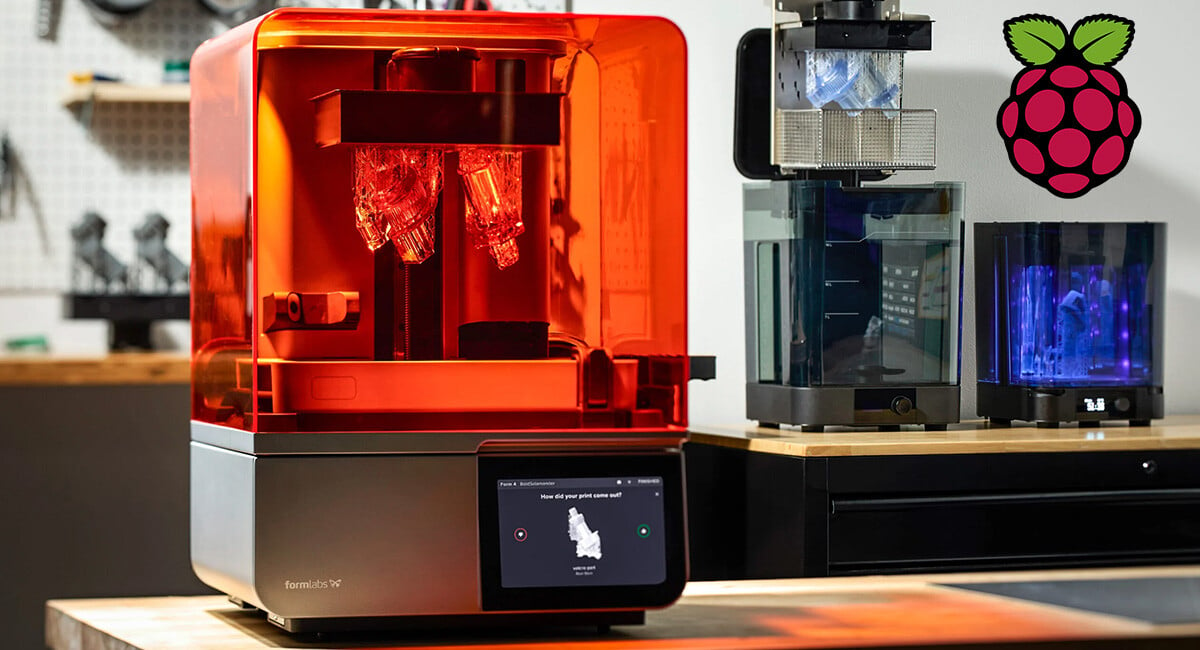

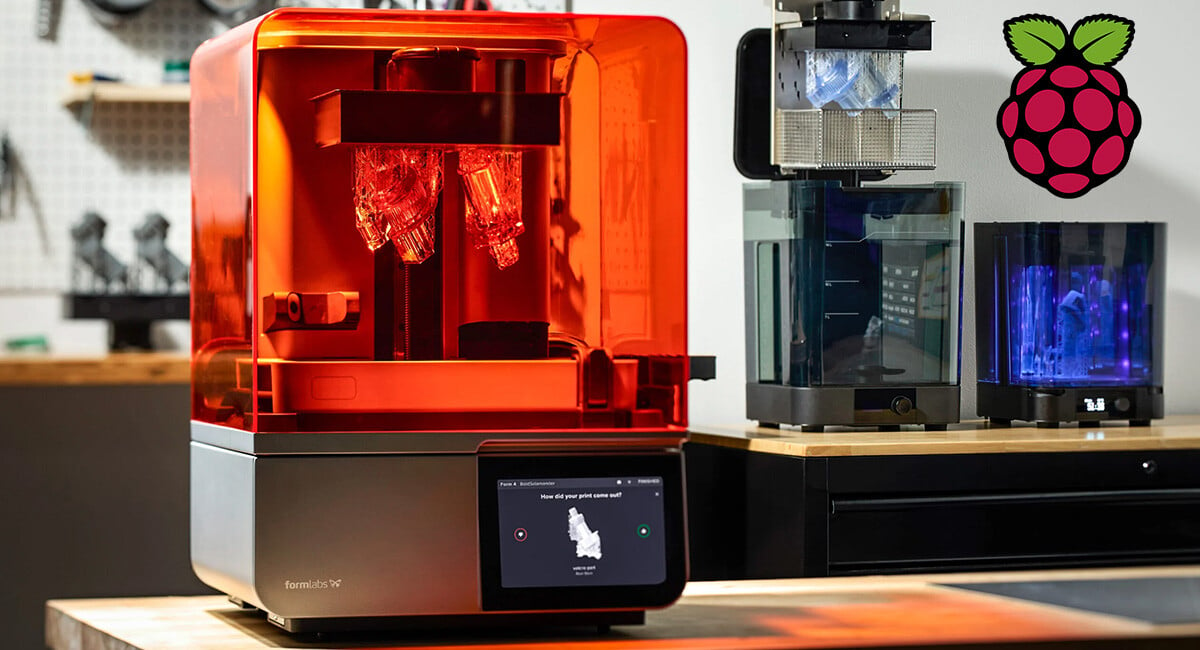

Using Raspberry Pi Compute Module 4 to power its latest 3D printer, Form 4, Formlabs increased the speed, quality, and success rate of printing for its flagship line, providing a reliable, high-power solution capable of serving both industrial and commercial customers.

Original Source - Raspberry Pi

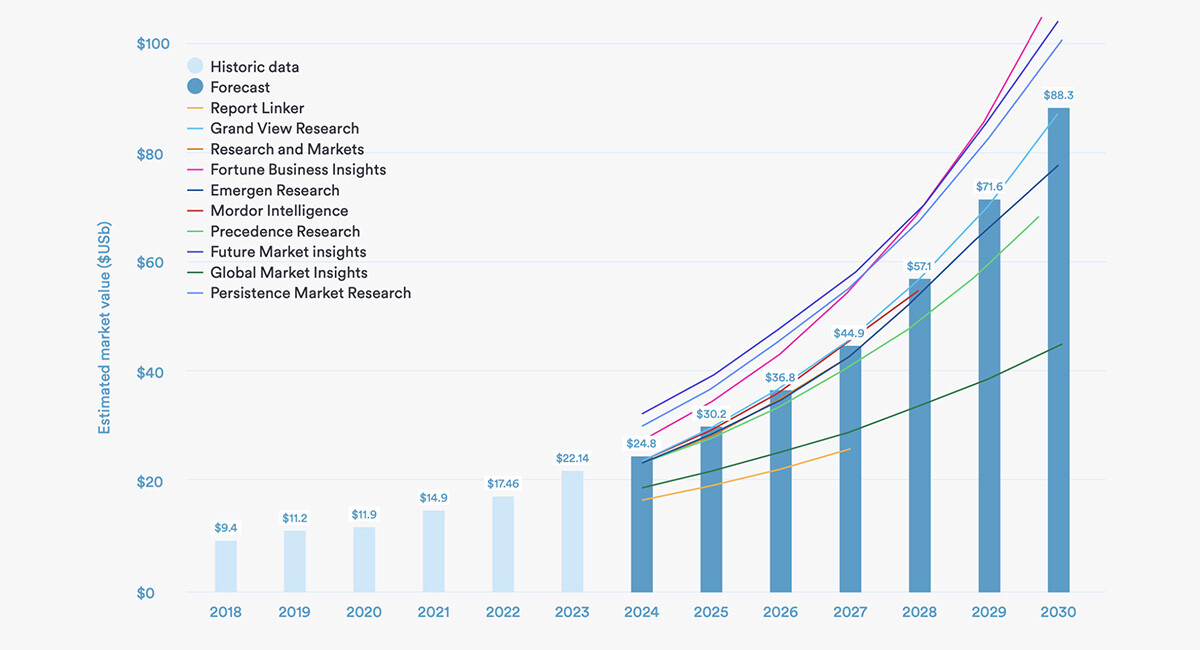

Formlabs is an American company specialising in the development and manufacture of 3D printers as well as related software and materials. Founded in 2011, the company was the first to build a 3D printer capable of achieving industrial, professional part quality at an affordable price. Since then, Formlabs has become the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world. Now, Formlabs’ products serve professionals across a wide range of industries, including engineering, manufacturing, automotive, aerospace, medical, education, entertainment, and more.

When kicking off the development of its latest flagship 3D printer, Form 4, the team at Formlabs realised a need to upgrade the SOM (system-on-module) it had used for a few years. This would be necessary to fulfill the increased computational and peripheral requirements of the system.

Formlabs printers have various apps running in the background to deliver fast and accurate printing and a good user experience. These are responsible for moving motors, curing resin, regulating temperatures, applying calibration, sensing and reacting to abnormalities, logging critical events, establishing wired / wireless communications, maintaining security, and so on. Accomplishing all these functionalities, along with the new software features Formlabs intended to develop, demanded enhanced computing power; Form 4 had the additional requirement to drive two high-resolution displays and one camera simultaneously. The existing SOM fell short in terms of CPU, RAM, and graphics capabilities.

Around that time, a notable mindset shift within Formlabs was giving priority to off-the-shelf solutions. Until then, SOMs had been developed in-house. In light of how fast the processor industry evolves and the size of the opportunity cost, developing and maintaining custom SOMs no longer seemed economical, even more so with the emergence of cost-effective SOMs like Raspberry Pi Compute Module 4.

Form factor was another critical element. The desirable form factor was a module with mezzanine connectors, allowing for board-to-board mounting onto a carrier board. This would offer clean and robust high-speed connections, as well as the flexibility to tailor the carrier board to Formlabs’ application. SBCs (single-board computers) were excluded for this reason.

Kononsky discovered research from the 1980s that proved it’s possible to calculate the specific gravity, fermentation activity,

After extensive part-searching and evaluation, Formlabs concluded that Raspberry Pi Compute Module 4 was the best fit for Form 4, specifically the CM4102000 variant (Wi-Fi, 2GB RAM, no eMMC). The module was plugged into Formlabs’ motherboard, where it works as the main compute engine of the product, in tandem with an i.MX RT1050 MCU, which is geared towards handling real-time tasks. A 32GB eMMC was placed on the motherboard so that data could be retained even when the module was replaced. The ability to disable Wi-Fi using a jumper and the option to switch to a non-wireless variant came in handy when addressing the stringent security needs of military and government customers.

High-speed peripherals that Compute Module 4 richly provides were allocated to key subsystems: HDMI and MIPI-DSI are responsible for driving two high-resolution LCDs, with the GPU exclusively dedicated to seamlessly operating the ‘exposure LCD’ used to mask UV light; MIPI-CSI is allocated to a 5MP camera, which produces timelapse videos; USB is used for printer-to-computer or printer-to-accessory communications, for which the OTG (on-the-go) function is useful, and Ethernet and Wi-Fi are used for interacting with Formlabs’ desktop and web applications.

One limitation the company faced was the USB interface numbering only one — when the OTG function is needed, adding a hub is not a practical option. Instead of creating a second USB from another peripheral, Formlabs chose to develop a peripheral-agnostic communication protocol and leverage it to eliminate internal USB usage. Since then, the launch of Raspberry Pi Compute Module 5 with two additional USB ports has eliminated the need for such protocols, something Formlabs considers a “clear plus” for itself and other Compute Module users.

Due to the common misconception that Raspberry Pi technology is only suitable for hobbyist projects, doubts emerged within Formlabs during the decision-making process. Nobody argued its performance–price ratio, which was undoubtedly best-in-class. However, other questions like “Is it easy to develop with?”, “Is it secure?”, “Is it reliable long-term and at scale?”, and “Can we buy them in volume?” arose.

Ultimately, Compute Module 4’s performance spoke for itself. Yocto-based Linux development was smooth, with publicly available Raspberry Pi layers being mostly plug and play. The level of security Formlabs could achieve with Compute Module 4 was sufficient for its purposes, and the failure rate of the module has proven extremely low across tens of thousands of Form 4 units already out in the field. Supply has never been an issue either, even in the midst of the global silicon shortage, thanks to Raspberry Pi’s effort to keep the manufacturing line running and the tight coordination between the two companies to ramp up allocation according to the usage forecast.

When a product is market-proven by scale, it is hard to deny, and multi-million-per-year sales of Raspberry Pi products speak to their versatility, quality, and reliability. This is often a stronger testimonial than anything else, and Formlabs took it seriously when deciding to move forward with Raspberry Pi.

With Compute Module 4, Formlabs saved on time and cost to design, debug, and maintain a custom SOM. Time spent on certification was short, and the motherboard redesign and software porting associated with replacing the SOM went smoothly, meaning Formlabs was able to spend that time and money elsewhere to maximise user value.

Implementing a consistently high-quality, well-documented device also meant little time spent on dealing with technical issues during product development and post-launch. When issues did occur, Raspberry Pi’s Product Information Portal (containing many approval notes and compliance reports important to industrial customers) and user forums were helpful resources. All of the above contributed to reducing product development time and in turn to Formlabs hitting its time-to-market target.

As for price, adopting Compute Module 4 resulted in about $30 BOM cost reduction compared to the previous SOM. The company was surprised by the difference, since the original SOM was a fully custom, chip-down implementation, which is typically expected to yield a lower BOM. Considering the superior performance of Compute Module 4 and the significant upfront investment that such custom solutions entail, taking the OTS route has become a no-brainer in recent years.

Compute Module 4 has also contributed to an improved user experience. Form 4 is receiving positive feedback for its speed, print quality, and print success rate. Its UI screen is crisp and responsive, and its camera is generating charming timelapse videos that Formlabs’ users love. Various connection channels used to talk to the company’s proprietary user-facing apps like PreForm or Dashboard also deliver convenience. Several metrics indicate that Form 4 is the highest-user-satisfaction product Formlabs has made to date.

Formlabs was left with no doubt that Compute Module 4 was the perfect fit for Form 4. Throughout the process of integrating Compute Module 4 into the product and bringing it to market, Formlabs saw firsthand the module’s suitability for industrial / commercial applications like its own. “Collaborating with Raspberry Pi has also been a pleasurable experience along the way,” the team adds. “We are glad that this collaboration led to a win-win situation for users and both companies.”

Subscribe to the blog for the latest updates