NASA on AM enabled Rotating Detonation Rocket Engine

Thomas Teasley, a liquid propulsion engineer at NASA’s Marshall Space Flight Center (MSFC), explains how additive manufacturing is a key component in developing the Rotating Detonation Rocket Engine (RDRE), a transformative propulsion system that leverages detonative combustion.

Original Source - 3D Printing Industry

The Rotating Detonation Rocket Engine generates thrust through continuous, spinning detonation waves within a circular combustion chamber. Compared to traditional subsonic combustion engines, it achieves higher efficiency and specific impulse or how effectively a rocket uses its propellant.

This engine may enable more efficient and reusable propulsion systems for future missions. This innovation relies on additive manufacturing (AM) laser powder bed fusion and specialized NASA alloys, such as GRCop-42 for thermal conductivity and GRX-810 for extreme temperature resilience. These materials and techniques facilitate the creation of complex integrated structures, including coolant channels and injector orifices, that are impossible to machine traditionally. Rigorous testing of temperature, pressure, and vibratory responses ensures reliability under the severe conditions of spaceflight.

The NASA MSFC Rotating Detonating Rocket Engine together with Venus Aerospace and REM Surface Engineering is nominated for the 2024 Aerospace, Space or Defence Application of the year.

Can you describe your application and how it differs from existing approaches in the market?

Thomas Teasley: The Rotating Detonation Rocket Engine uses detonative combustion instead of slow or subsonic combustion like traditional rockets to achieve superior combustion and specific impulse efficiencies. The improvement in efficiency is so dramatic that the combustion environment is nearly impossible to contain and keep hardware cool. This is where additive manufacturing and specialized NASA alloys like GRCop-42 and GRX-810 have enabled the RDRE to become a reality. Ultimately, propulsion systems for space exploration must become more efficient and reusable which AM, specialized alloys, and the RDRE itself allow for.

What specific problem does your application solve, and what makes it a groundbreaking solution in the 3D printing space

Thomas Teasley: The RDRE requires complex integrated structures such as coolant channels, flow paths, and injector orifices that just cannot be traditionally machined with typical alloys. Propulsion systems are always improving in performance and the combustion environment is only becoming more extreme. This engine technology requires the use of AM and specialized alloys to become a reality and enables a broader trade space of future human crewed missions to the Moon and Mars.

Can you elaborate on the specific additive manufacturing techniques and materials you employed in your project and why they were chosen over traditional manufacturing methods?

Thomas Teasley: Laser powder bed fusion is the primary AM technique along with a copper alloy known as GRCop-42 and Nickel alloy known as GRX-810. GRCop-42 is a high conductivity alloy that is used for the primary hot wall of the thrust chamber and can rapidly transfer heat away from the wall to meet a minimum temperature requirement and prevent melting. GRX-810 is an extreme environment super alloy that allows for high strength at high temperature.

What measures have you implemented to ensure the reliability, consistency, and quality control of your AM components, especially given the rigorous demands of aerospace, space, or defense applications?

Thomas Teasley: We have made numerous temperature and pressure measurements in critical manifold interfaces in addition to thrust and dynamic vibratory responses of the engine system. Each of these measurements allow us to confirm the severity of the combustion environment and prove how enabling AM and these specialized alloys have been.

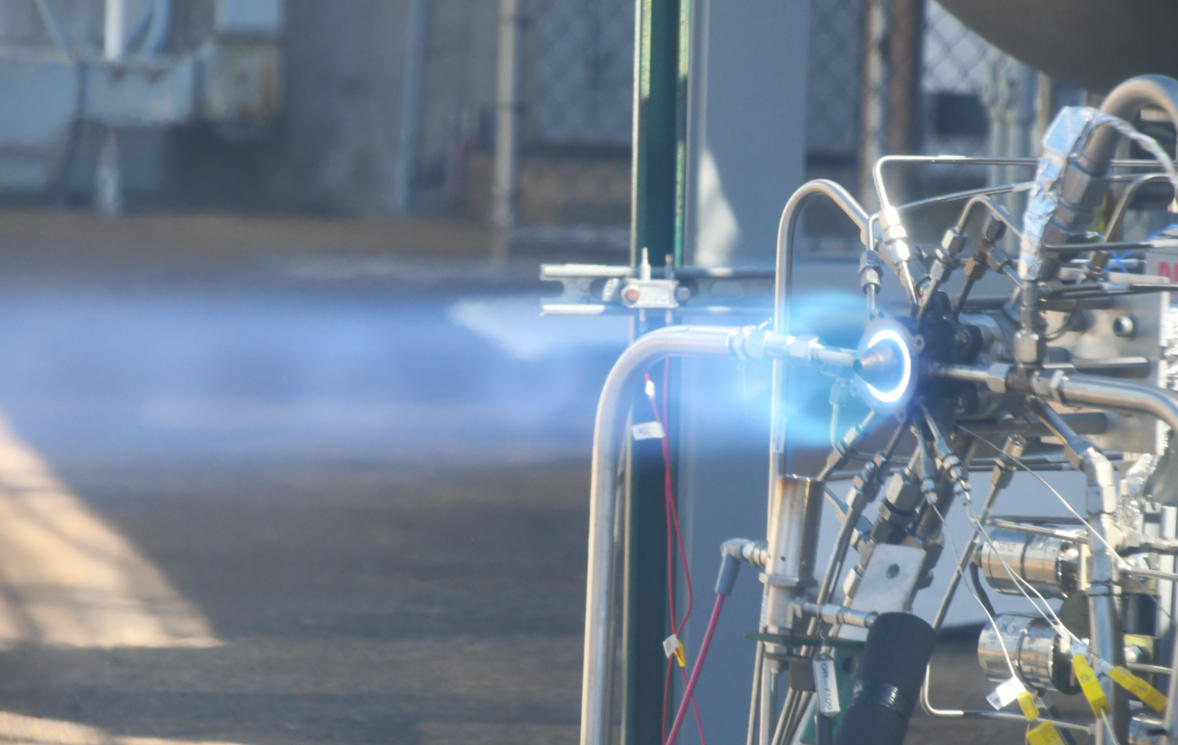

NASA Subscale 1,000 lbf class RDRE. Methane/Oxygen. World record-holding test at 750 psi for an RDRE. Photo via NASA.

NASA Subscale 1,000 lbf class RDRE. Methane/Oxygen. World record-holding test at 750 psi for an RDRE. Photo via NASA.

How does your innovation address the industry’s current pain points, such as supply chain vulnerabilities, production lead times, or material performance limitations?

Thomas Teasley: The RDRE requires the use of GRCop-42 and GRX-810 which opens up the existing supply chain to improving the availability of these alloys. This is particularly the case when dozens of industry partners are expressing interest in the technology and investing in these alloys for use with their specific engine applications.

What role does collaboration play in your work, whether with research institutions, government agencies, or industry partners, and how have these collaborations contributed to your success?

Thomas Teasley: Direct collaboration with industry, government, and academia is what enables the development and widespread use of the RDRE propulsion technology. Without partnerships, its maturation would not be possible.

Is there anything else you would like to add?

Thomas Teasley: The RDRE has been stated to be the next step in space exploration propulsion technology by multiple industry and government partners. Its performance benefits are real and substantial and will very likely be flying on a space vehicle in the next 5 to 10 years given its current rate of development.

NASA Full Scale 5000 lbf class lander RDRE. Kerosene/Oxygen. Photo via NASA.

NASA Full Scale 5000 lbf class lander RDRE. Kerosene/Oxygen. Photo via NASA.