When you’re an internationally respected, multi-disciplinary infrastructure consultancy, choosing equally trustworthy technology to stake your reputation on isn’t something to be taken lightly.

Graham Watson, Senior Engineering Surveyor for Opus International Consultants says that FARO’s Focus3D X330 laser scanner has proven itself both trustworthy and in high demand on a number of different projects Opus has been engaged on.

“The X330 is our second scanner, but the first one we’ve purchased,” he says. “Prior to the X330 we hired a FARO S120 through Synergy Positioning Systems. The hire unit worked well for us at the time, but we could see the increase in demand for this technology as an ongoing part of our operation, so we decided to invest in the new laser scanner when it arrived on the market.”

Graham, who in his role is essentially responsible for running the laser scanner in Christchurch, says that the portability of the FARO is a huge bonus, as it is required on a variety of projects all over the country.

“The unit actually spends a lot of time in transit as there’s an almost continual need for it somewhere. In theory you could probably take it onto a plane as cabin baggage, although we tend to courier it to wherever it’s needed. It fits into a ruggedised hard case, so we know it’s well protected.”

Graham says the majority of Opus’ work with the X330 is within the short-to-medium scanning range. The nature of a lot of the consultancy’s work means that scan detail from confined environments or engineered surfaces is required. So to this particular entity, a 50m scan is more relevant than a full 300m scan.

“We certainly do get involved in geotechnical scans of environments such as slips, where we’re looking at 100m scans, but generally speaking any greater distance than that is a bonus.”

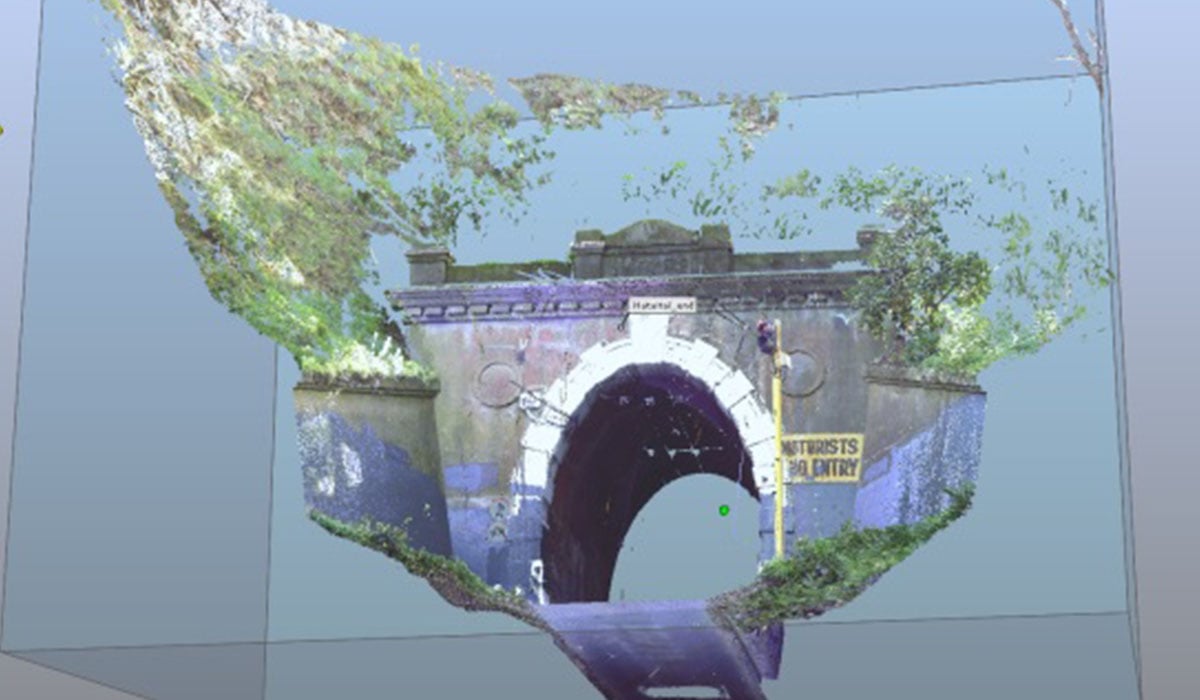

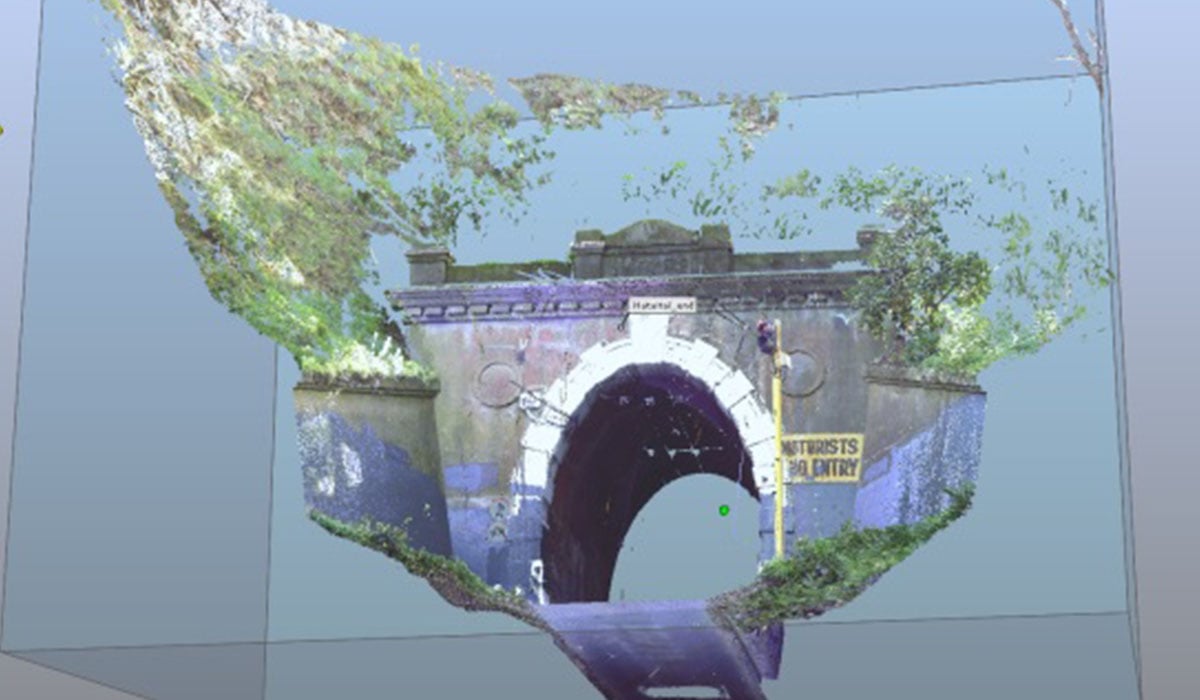

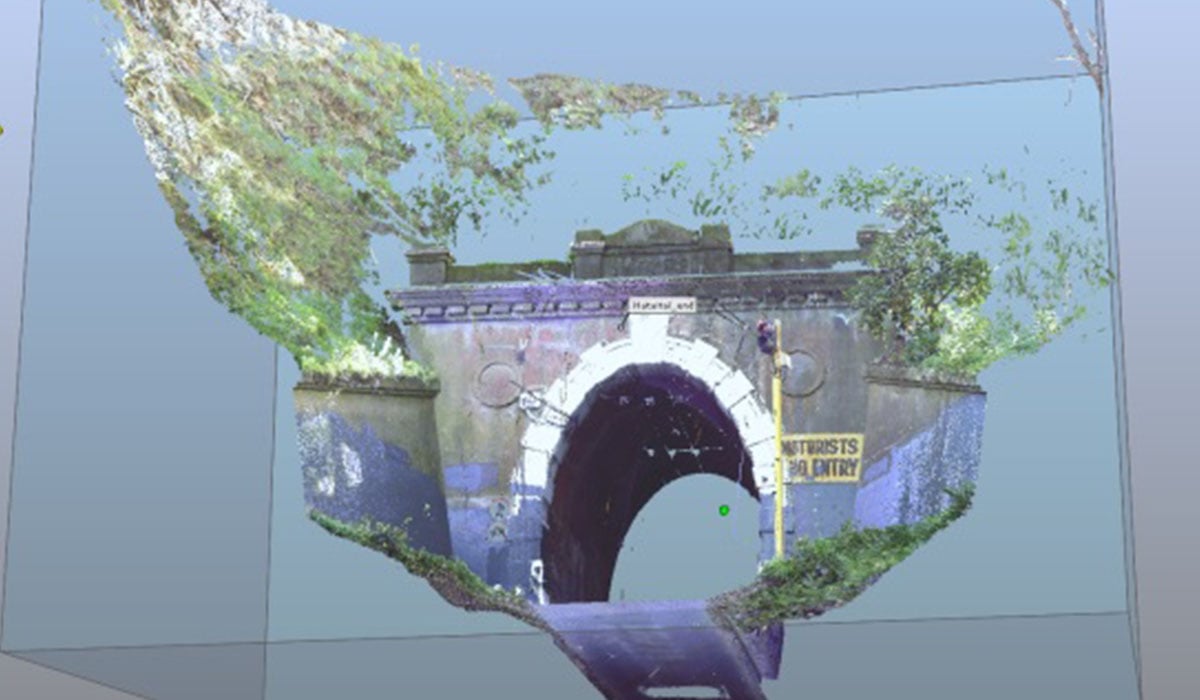

But while the distance of the typical scan for Opus isn’t at the X330’s full range, the breadth of projects the consultancy has already utilised it for is remarkable. From archaeological dig sites in historic areas to tank deformation reporting for the oil and gas industry, to scanning subterranean tunnels and monitoring structural integrity in major demolition works: the FARO Focus3D X330 is helping Opus do it all.

“The main impetus to even start using the laser scanner was when we began monitoring storage tanks for the oil and gas industry,” says Peter Troon, Opus New Plymouth’s Survey Team Leader.

“We perform regular checks of the tanks and utilise the laser scanner to record against existing data for signs of tank deformation. We’re looking at the health of the steel in the structure, completing verticality checks of the walls and scanning the tank floor as well.”

While oil tanks are one interior the X330 is used in to ensure there are no unexpected changes to the structure, another interior environment being scanned regularly nearby is constantly changing: the large scale demolition project at the decommissioned New Plymouth power station.

“Naturally the environment at the power station is a hazardous one,” continues Peter. “There are a lot of structural elements to consider and a lot of these elements are actually suspended from the ceiling, so the dismantling happens from the bottom up. “We started structural stability checks with the laser scanner last year, spending five full days on-site initially. This sort of work is ongoing and we work with the contractors to go back in as separate sectors of the site are demolished.”

One of Opus’ more challenging projects – and one Peter says featured a good mix of cutting-edge technology and Kiwi ingenuity – was a tunnel scan for TrustPower at the headwaters of Lake Mangamahoe in Taranaki.

That was a working environment that challenged both man and machine. We had to scan the interior of a 500m long tunnel which travels horizontally back into a hill and then up a steep vertical climb, so we were working in knee deep water with only portable lights and constantly checking for gas.

“Despite having the technology of the X330 at hand, there was still an element of jury-rigging a solution involved as well: in order to get the laser scanner mobile but retain a smooth transition through the tunnel, we got an old office chair base which formed a perfect ring to mount the X330 on in order to drag it through the tunnel. Naturally we used GPS control and levelling to ensure the unit was stable, but it was certainly an interesting combination of the latest technology and whatever we had to hand.”

In Christchurch, Graham Watson says that the FARO Focus3D X330 has also recently been used to scan some sites of archaeological importance at Lyttelton.

With the scanner Opus was able to record the position of the original footprint of the Lyttelton Borough School (1875) which was unearthed by Opus archaeologists. The school was simply rebuilt on top of the old foundations in 1941, with little care taken for the historic integrity of the existing site. The substantial wall around the site (built by Lyttelton convicts) was also scanned.

I can see the laser scanner being utilised for this sort of archaeological work more and more in the Christchurch area as the city’s rebuild continues and developers strike sites of potential historic significance,” says Graham, who has also used the X330’s predecessor – the S120 – to scan church structures for different diocese in the city.

Graham says that Opus has been very pleased with both the robustness of the FARO unit and the technical back-up they’ve received from FARO distributor Synergy Positioning Systems, saying that there has been barely any issues to speak of at all.

We’re heavily AutoDesk based at Opus and, while the laser scanner software is very usable, you do need to have the right data support infrastructure to manage some of the files: this is something we’re sure to educate clients on.

“It’s all very well being able to use scan data like this for project work, but some of the files we work with are 10GB or 20GB, so clients need the appropriate data processing ability: even the ability to simply store it.”

Overall though, Opus International Consultants is still discovering new applications and environments in which to use the laser scanner.

“The technology that’s built into laser scanners like the FARO Focus3D X330 represents a huge step in our industry,” concludes Peter Troon. “It comes in a small, portable package but I think the likes of the X330 represents for scanning what the total station represented for surveying 20 years ago. It’s fantastic to be able to utilise a tool of trade like this.”