Filament Capable Large Format 3D Printer

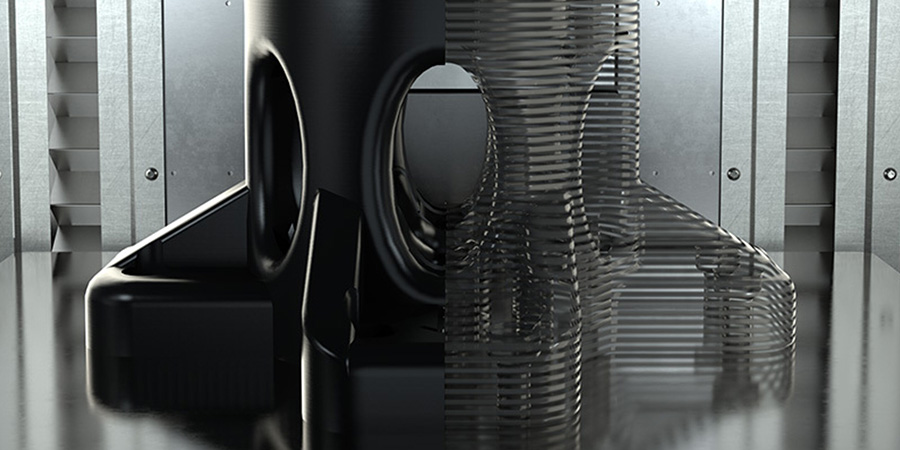

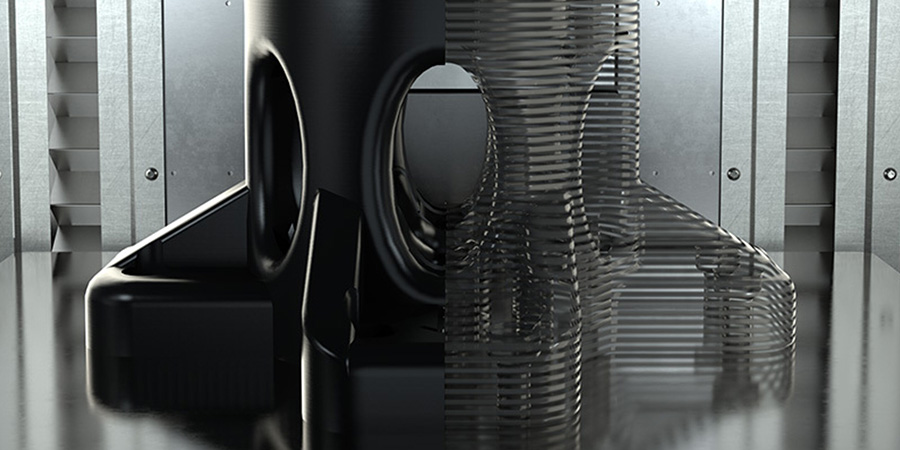

FX20 Large Format 3D Printer

Massive builds, faster prints, continuous fibre reinforcement.

FX20 pushes boundaries for demanding industries.

Scale & Speed Unleashed

The FX20 transcends the boundaries of traditional 3D printing. Witnessing a harmonious union of size and speed, it allows you to print larger designs at remarkable speeds. This innovative breakthrough unlocks the full potential of The Digital Forge on a grander scale than ever before. Imagine your ideas coming to life, no longer restricted by size limitations. With the FX20, push the boundaries of what's possible and embark on a journey of unlimited design freedom.

Flight-Ready Parts at Scale

This large-format powerhouse tackles performance tooling, fixtures, and even flight-ready production parts, all empowered by the strength and precision of continuous carbon fibre reinforcement. No longer confined by traditional methods, imagine printing VEGA filament components with unparalleled strength and heat resistance, ready to soar through the skies.

The FX20 is not just a printer, it's a launchpad for innovation, propelling your vision into the future.

Precision Meets Performance

The FX20 isn't just a 3D printer, it's a productivity powerhouse. This precision-engineered machine boasts breakthrough reliability and performance, ensuring your production runs smoothly and efficiently. Built with intuitive sensor-driven technology, the FX20 offers a simpler user experience, empowering you to focus on innovation, not operation. Unleash the potential of production-ready printing with the FX20 and witness your vision transform into reality, with unwavering precision and performance every step of the way.

Large volume VEGA filament compatible the FX20 delivers robust, heat-resistant 3D printed parts.

Print large, complex parts in one go thanks to the FX20's expansive build volume, eliminating assembly steps.

Leverage the superior strength, heat resistance, and flame retardancy of VEGA filament for demanding applications.

From aerospace to automotive, the FX20 tackles diverse challenges with robust, high-temperature 3D printed parts.

State-of-the-art technology simplifies operations, empowering you to focus on design, not troubleshooting

MARKFORGED FX20 Features

Physical Dimensions

Width 1325 mm

Depth 900 mm

Height 1925 mm

Weight 530 kg / 1170 lbs

Build Volume

Width 525 mm

Depth 400 mm

Height 400 mm

Forge Process

Printing Process

Fused Filament Fabrication, Continuous Fiber Reinforcement

Z Layer Resolution

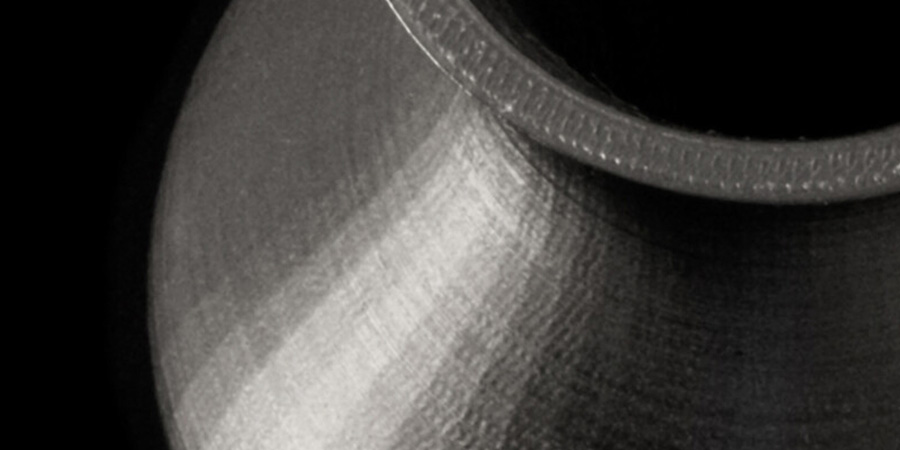

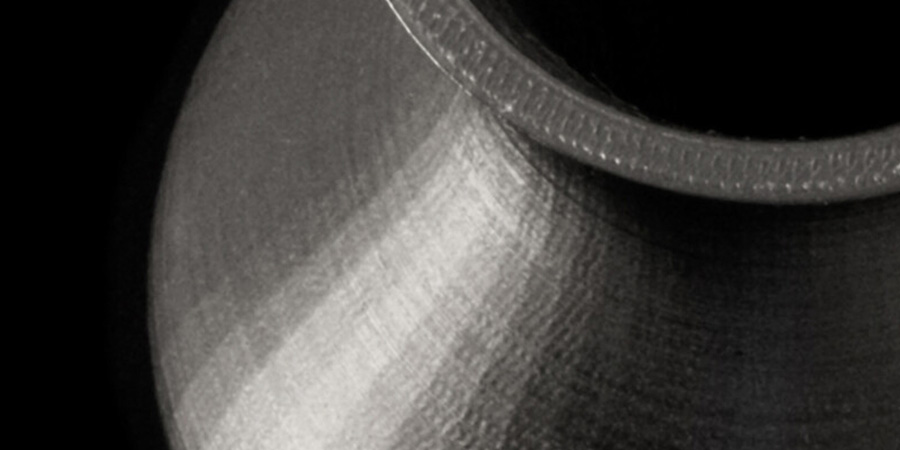

50 μm - 250 μm

Printing Media

Polymer Filament, Continuous Fibers

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement

Print Bed

Precision Machined Aluminum

MARKFORGED FX20 Materials

Onyx

This nylon, infused with microscopic carbon fibres, forms the hidden backbone of Markforged's robust composite parts. Read more

VEGA

Unlocking groundbreaking aerospace applications, this PEKK composite combines ultra-performance carbon fiber and 3D printing precision. Read More

ULTEM 9085 Filament

Advanced PEI thermoplastic, reinforced with continuous carbon fibre for unparalleled strength and durability. Read more

Onyx FR

NCAMP-approved and UL 94 V-0 rated, this flame-retardant micro carbon fibre nylon exceeds the most stringent safety standards. Read more

Carbon Fiber

Continuous carbon fibre forms the hidden foundation, granting composite parts incredible strength rivalling 6061-T6 Aluminum. Read more

Carbon Fiber FR

Lighter than aluminium, yet just as strong, carbon fibre composites open new possibilities for demanding applications. Read more

Performance Specifications

| Printer Properties | ||||||||

| Process | Fused Filament Fabrication, Continuous Fiber Reinforcement | |||||||

| Build Volume | Single-nozzle builds: 525 x 400 x 400 mm (20.6 x 15.7 x 15.7 in) Multi-nozzle builds: 500 x 400 x 400 mm (19.7 x 15.7 x 15.7 in) |

|||||||

| Weight | 530 kg (1170 lbs) | |||||||

| Machine Footprint | 1325 x 900 x 1925 mm (52.2 x 35.5 x 75.75 in) | |||||||

| Temperature Control | Up to 200°C steady-state | |||||||

| Print System | Direct-drive print head with three nozzles (two plastic, one fibre) | |||||||

| Power | 200-240 VAC 2W+PE 40A // 200-240 VAC 3Ø+PE 24A // 347-415 VAC 3Ø+N+PE 14A; 50-60 Hz | |||||||

| Safety | IEC/UL/CSA 62368-1 certified, CE Marked, EU Machinery Directive compliant | |||||||

| Materials | ||||||||

| Plastics | Vega, ULTEMTM 9085 filament, Onyx, Onyx FR | |||||||

| Continuous Fibers | Carbon Fibre, Fibreglass, Aramid Fibre (Kevlar®), High-Temperature Carbon Fibre, Carbon Fibre FR | |||||||

| Part Properties | ||||||||

| Layer Height | 50 μm minimum, 250 µm maximum | |||||||

| Accuracy | +/- 125 µm or +/- 0.0015 mm per mm (whichever is greater) | |||||||

| Software | ||||||||

| Eiger | Secure digital library, powerful slicer, and printer management (premium options available at cost) | |||||||

| Security | Two-factor authentication, org admin access, single sign-on, MFP print files encrypted by default and tamper-resistant | |||||||

| Connectivity | Eiger connection and over-the-air updates via Ethernet | |||||||

Not sure which solution is right for your application?

Related Products

Eiger Software

MARKFORGED EIGER Software. Forget fragmented workflows. Streamline your entire Additive Manufacturing process with our multifunctional software suite. Seamlessly design, optimise, print, and manage your 3D products, achieving peak efficiency and control.

Onyx

MARKFORGED ONYX. This nylon, infused with microscopic carbon fibres, forms the hidden backbone of Markforged's robust composite parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

VEGA

MARKFORGED CARBON FIBRE Continuous carbon fibre forms the hidden foundation, granting composite parts incredible strength rivalling 6061-T6 Aluminum.A special Carbon Fiber variant is compatible with VEGA Filament.

Ready to Get Started?

Get in touch to book a demo or find out how we can help you sell on {Marketplace}

Ready to Get Started?

Get in touch to book a demo or find out how we can help develop and grow your business.