The World’s First Industrial Metal and Composite Printer

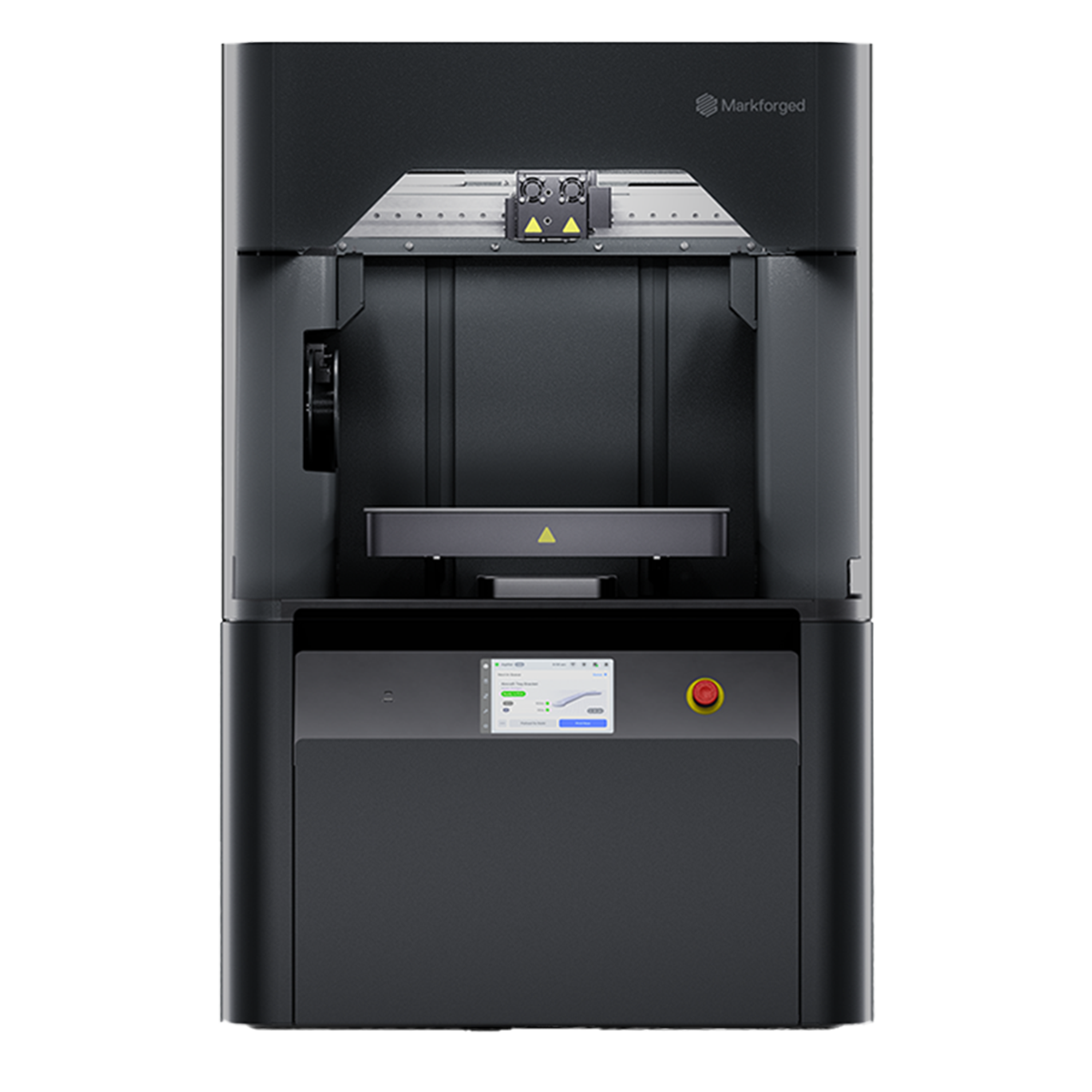

FX10 Metal & Composite 3D Printer

The ultimate all-in-one solution for metal and composite printing, tailored to your factory's needs.

Composite

The FX10 delivers the strength, surface finish, and reliability of our industrial machines, but with a cutting-edge sensor package and flexible modular design. This allows users to seamlessly upgrade to a metal printing engine. The heated print chamber and automated spool changeover enable the production of large, high-quality parts. Plus, its laser micrometer and integrated vision module capture detailed composite part images for precise calibration, inspection, and verification.

Metal

The FX10 is built with a modular system architecture which allows users to unlock metal print mode with a simple swap of the

print engine. With the additional purchase of a Metal Kit, the FX10 becomes the world’s first industrial metal and composite

printer. Reliably print composite and metal parts to drive superchare manufacturing and productivity on your factory floor.

Metal enabled FX10 printers will need a Wash-1 and a Sinter-1 or Sinter-2 to wash and sinter green parts into production-ready

metal parts.

World First!

The FX10 is a cutting-edge industrial 3D printer designed to revolutionize your manufacturing processes. Its modular design allows for easy upgrades and customization, while its advanced technology ensures the production of high-quality parts with unmatched precision and strength. By streamlining production workflows and reducing lead times, the FX10 empowers businesses to increase efficiency, reduce costs, and gain a competitive edge in today's demanding market.

Elevate Your Manufacturing with the FX10

The FX10's advanced technology delivers unmatched accuracy and speed, ensuring your parts meet the highest standards of quality.

Streamline your production processes and minimize waste with the FX10's efficient design. Enjoy significant cost savings while increasing your output.

Don't miss out on the opportunity to revolutionise your business with the FX10. Contact us now to learn more and discover how this innovative 3D printer can take your manufacturing to new heights.

Don't settle for less. This industrial-grade 3D printer delivers unparalleled composite & metal performance and precision!

MARKFORGED FX10 Features

Physical Dimensions

Width 760 mm

Depth 640 mm

Height 1200 mm

Weight 122 kg / 270 lbs

Build Volume

Width 375 mm

Depth 300 mm

Height 300 mm

Composite Specs

Printing Process

Fused Filament Fabrication, Continuous Fiber Reinforcement

Z Layer Resolution

125 μm - 250 μm

Printing Media

Polymer Filament, Continuous Fibers

Internal Part Geometry

Closed Cell Infill with Continuous Fiber Reinforcement

Print Bed

Precision Machined Aluminum

Metal Specs

Printing Process

Metal Fused Filament Fabrication

Z Layer Resolution

127µm post-sinter

Printing Media

Bound Powder Filament

Internal Part Geometry

Closed Cell or Solid Infill

Print Bed

Heated, Auto Leveling, Replaceable Print Sheets

MARKFORGED FX10 Materials

Onyx

This nylon, infused with microscopic carbon fibres, forms the hidden backbone of Markforged's robust composite parts. Read more

Onyx FR

NCAMP-approved and UL 94 V-0 rated, this flame-retardant micro carbon fibre nylon exceeds the most stringent safety standards. Read more

Onyx ESD

Onyx ESD is a static-dissipative chopped carbon fiber nylon material, precision-engineered for a tight range of surface resistance. Read more

Carbon Fiber

Continuous carbon fibre forms the hidden foundation, granting composite parts incredible strength rivalling 6061-T6 Aluminum. Read more

Carbon Fiber FR

Lighter than aluminium, yet just as strong, carbon fibre composites open new possibilities for demanding applications. Read more

17-4PH Stainless Steel

17-4PH Stainless Steel is a multipurpose steel used for industrial applications. Heat-treatable to 36 HRC and possessing 95% wrought strength. Read More

316L Stainless Steel

Corrosion-resistant stainless steel used in food and beverage, marine, and manufacturing applications. Read more

Performance Specifications

| Printer Properties | ||||||||||

| Composite | Metal | |||||||||

| Process | Fused Filament Fabrication, Continuous Fiber Reinforcement | Metal Fused Filament Fabrication | ||||||||

| Build Volume | 375 x 300 x 300 mm | 375 x 300 x 300 mm (14.8 x 11.8 x 11.8 in) | ||||||||

| Weight | 122 kg (270 lbs) | 122 kg (270 lbs) | ||||||||

| Machine Footprint | 760 x 640 x 1200 mm | 760 x 640 x 1200 mm | ||||||||

| Temperature Control | Heated chamber reaches up to 60°C ready-state | Heated chamber reaches up to 60°C ready-state | ||||||||

| Print System | Direct-drive print head with two nozzles (one plastic, one fiber), automatic material changeover | Swappable metal print engine includes metal print head, material routing block, and material tubing. Automatic material changeover | ||||||||

| Power | 100-120 VAC 12A /15A 200-240 VAC 6A / 8A | 100-120 VAC 12A /15A 200-240 VAC 6A / 8A | ||||||||

| Safety | UL 2011/CSA C22.2#301 certified, CE Marked, EU Machinery Directive compliant | UL 2011/CSA C22.2#301 certified, CE Marked, EU Machinery Directive compliant | ||||||||

| Materials | ||||||||||

| Materials | Onyx®, Onyx FR, Onyx ESD, Carbon Fiber, Carbon Fiber FR | 17-4PH Stainless Steel, 316L Stainless Steel | ||||||||

| Part Properties | ||||||||||

| Layer Height | 125 μm minimum, 250 µm maximum | 127 μm post-sinter | ||||||||

| Software | ||||||||||

| Eiger | Secure digital library, powerful slicer, and printer management (premium options available at cost) | |||||||||

| Security | Two-factor authentication, org admin access, single sign-on, MFP print files encrypted by default and tamper-resistant | |||||||||

| Connectivity | Eiger connection and over-the-air updates via Ethernet | |||||||||

Not sure which solution is right for your application?

Related Products

Eiger Software

MARKFORGED EIGER Software. Forget fragmented workflows. Streamline your entire Additive Manufacturing process with our multifunctional software suite. Seamlessly design, optimise, print, and manage your 3D products, achieving peak efficiency and control.

Onyx

MARKFORGED ONYX. This nylon, infused with microscopic carbon fibres, forms the hidden backbone of Markforged's robust composite parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

Carbon Fibre

MARKFORGED CARBON FIBRE Carbon Fiber FR is a flame-retardant variant of Markforged’s unique, ultra-high-strength Continuous Carbon Fiber — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminum.

Ready to Get Started?

Get in touch to book a demo or find out how we can help you sell on {Marketplace}

Ready to Get Started?

Get in touch to book a demo or find out how we can help develop and grow your business.