The Complete Desktop FIM Package

What’s Included in FIM Desktop Package?

Unleash the power of desktop manufacturing with the all-inclusive Freeform Injection Molding (FIM) Desktop Package. This one-stop solution empowers you to print your own injection moulding tools and low-volume parts directly on your desktop, streamlining your entire product development process. Take control of your creations and accelerate innovation with the FIM Desktop Package.

Sustainable Resin 3D Printing

Print Green with the Eco-Conscious XiP

The XiP desktop resin 3D printer is designed with sustainability in mind, minimising its environmental impact throughout its lifecycle. From recyclable packaging to its core construction, the XiP prioritizes responsible practices. Its easily recyclable aluminium body ensures minimal environmental footprint, while the modular design allows for future upgrades, extending the printer's lifespan and reducing electronic waste. Choose the XiP and make a conscious choice for a greener future of 3D printing.

Affordable High-Speed 3D Printing

Unleash rapid production without breaking the bank with the XiP

The XiP desktop resin printer redefines affordability in high-speed 3D printing. Its open material platform lets you choose between validated Nexa3D resins for guaranteed quality or explore cost-effective third-party options. This flexibility, coupled with industrial-grade performance and a future-proof modular design, empowers you to create consistent, high-quality parts and prototypes faster and for less.

Bridging the Gap Between Design and Production

xMOLD Resin FIM Process

xMOLD Resin revolutionizes the path from concept to creation. This innovative resin unlocks the design freedom of resin 3D printing while seamlessly integrating with the final production materials of injection moulding. Through the acquisition of Addifab and its groundbreaking Freeform Injection Molding (FIM) process, xMOLD Resin empowers you to create high-quality injection moulding tools directly from your 3D printer, eliminating the need for complex mould creation and accelerating your time to market.

Compare to the Competition

What if there was a solution that ticked all the boxes?

Introducing the XiP – the high-speed, cost-conscious champion in the professional desktop resin 3D printing arena. Stop sifting through countless options. The XiP delivers exceptional print quality, blazing-fast speeds, and an open material platform for ultimate flexibility, all at a price point that won't break the bank.

Don't settle – choose the XiP and unlock the future of desktop resin printing.

Related Products

Xip Pro

Nexs3D xiP Pro: Blazing Speed Without Compromise

Forget the age-old dilemma of speed versus quality in 3D printing. The XiP Pro shatters this barrier with its revolutionary LSPc technology. This innovation utilizes a self-lubricating membrane, enabling the XiP Pro to achieve an industry-leading print speed of 24 vertical centimeters per hour. This translates to generating a full build volume in under two hours, a feat that was previously unimaginable. But speed isn't the only story – the XiP Pro delivers exceptional print quality and surface finish without compromise.

Experience the best of both worlds: blazing-fast printing paired with stunning detail and a smooth finish.

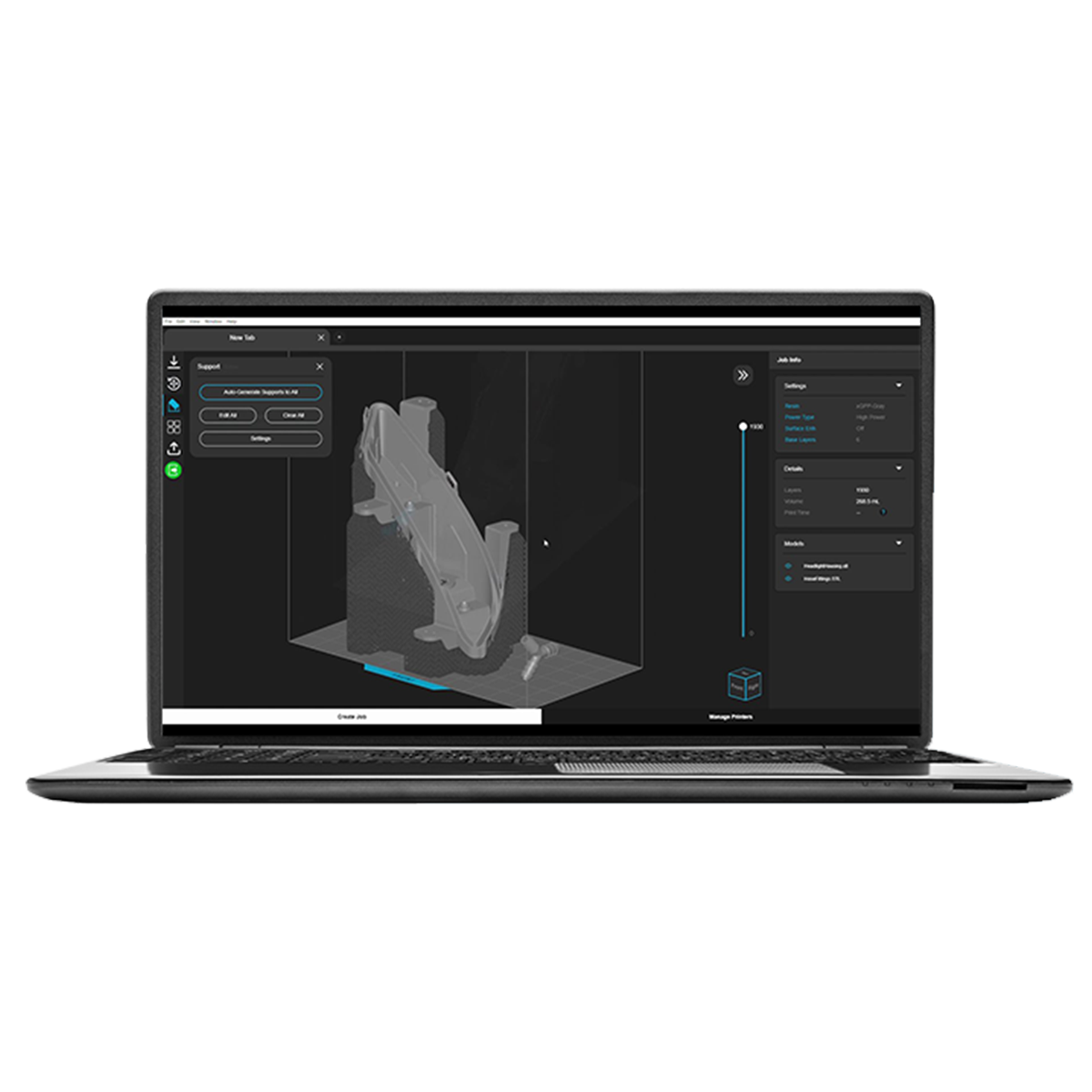

Software

NexaX: Your All-in-One 3D Printing Command Center

NexaX transcends mere software. It's a fully integrated ecosystem designed to streamline your entire 3D printing workflow. NexaX provides seamless API integration with a wide range of industry-leading software, including:

- Assembly Part Consolidation

- Generative Design for Additive Manufacturing

- Lightweighting Tools

- Automated Print Optimization

- Part Costing Estimator

- ROI Calculator

- MES Workflow Integration

This translates to significant time savings, increased efficiency, and maximised results. Print smarter, not harder, with NexaX.

Materials

Nexa3D Unmatched Open Material Platform

We empower you with a vast and ever-expanding library of qualified materials to fuel your creativity. Whether you require high-performance resins, versatile thermoplastics, or specialized options, Nexa3D has you covered.

For ultimate peace of mind, Nexa3D offers a comprehensive selection of pre-qualified materials. These materials undergo rigorous testing to guarantee optimal performance and compatibility with our printers, delivering consistent, high-quality results.

Explore the endless possibilities with Nexa3D's open platform and comprehensive library of qualified materials.

Revolutionising Flight Simulation with XiP Desktop 3D Printer

The Customer

In an industry where speed, accuracy, and cost-effectiveness are crucial, Yawman Flight teamed up with MotoCilino Engineering Service firm and Nexa3D to address the challenge of designing and developing a first-of-its-kind handheld controller for flight simulations. The Yawman Arrow is the fusion of a traditional handheld gaming controller and the unique flight controls found on aircraft of all sizes. Designed for precision and versatility, the Arrow brings together a traditional joystick, desktop throttle quadrant, and rudder pedals – and more – all into a handheld form factor.

The result is a breakthrough in both product innovation and manufacturing efficiency, with XiP Desktop 3D Printer playing a pivotal role in achieving success.

The Challenge

Create high-fidelity prototypes quickly and cost-effectively without investing in tooling early on in the development process

Yawman Flight faced the challenge of creating a unique flight simulator controller under significant time and budget constraints. The primary objectives were to develop a first-of-its-kind handheld flight simulator controller and complete the project rapidly and cost-effectively, without investing in costly injection molding tooling. Additionally, the team required high-quality surface finish and mechanical performance of all of the components so achieving injection molding-like quality quickly and affordably were critical to the success of the project.

Yawman Flight’s intended customer base is flight simulation enthusiasts and professionals in the aviation industry who demand high-quality, realistic flight simulation experiences. The flight simulation industry requires high-quality products that can meet strict specifications for part tolerances and mechanical performance in order to provide a truly realistic simulation experience.

“The XiP allowed us to create a final product that exhibits injection molded like qualities in terms of surface finish and performance, but without the costs and long lead times. We would’ve been delayed by as much as a year had we used another manufacturing method during the prototyping phase.”

Thomas Nield, Engineering Lead at Yawman Flight

The Solution

The XiP proved to be ideal tool for the job due to its accuracy and print speed

Yawman Flight collaborated with MotoCilino Engineering Service firm to develop a unique controller in record time, going through 17 different design iterations before validating the final assembly in just a few weeks. The final prototype controller consists of 36 different components, all of which were printed on the XiP desktop 3D printer using xABS3843 high-performance resin.

The team at MotoCilino chose to print the components on the XiP due to printer’s reliability and high print quality using performance grade resin that mimic mechanical properties of final production grade ABS. In fact, the finished controller visual aesthetic and mechanical performance was virtually indistinguishable from those components that were molded. “Printing on the XiP allowed us to deliver components to the Yawman team in half the time it would’ve taken us had we used another desktop SLA printer, and the print quality on the XiP is just superior,” said Paul Cilino, Owner of Motocilino.

The Benefit

Accelerated time to market by nearly a year and delivered high-fidelity prototypes at a fraction of the cost

The team was able to finalize the design and deliver a high quality prototype with injection molding-like surface finish and mechanical performance quickly and cost effectively. The finished assembly included over 36 printed components, all virtually indistinguishable from its injection molded counterparts in both finish and mechanical performance. As a result, the team is now ready to scale to production as they prepare for commercial launch in July, 2023, on the heels of tremendous initial demand received during its beta launch earlier in the year.

The Fastest Growing Products in Advanced Manufacturing

have arrived.

We are confident that our products and solutions will exceed your expectations.