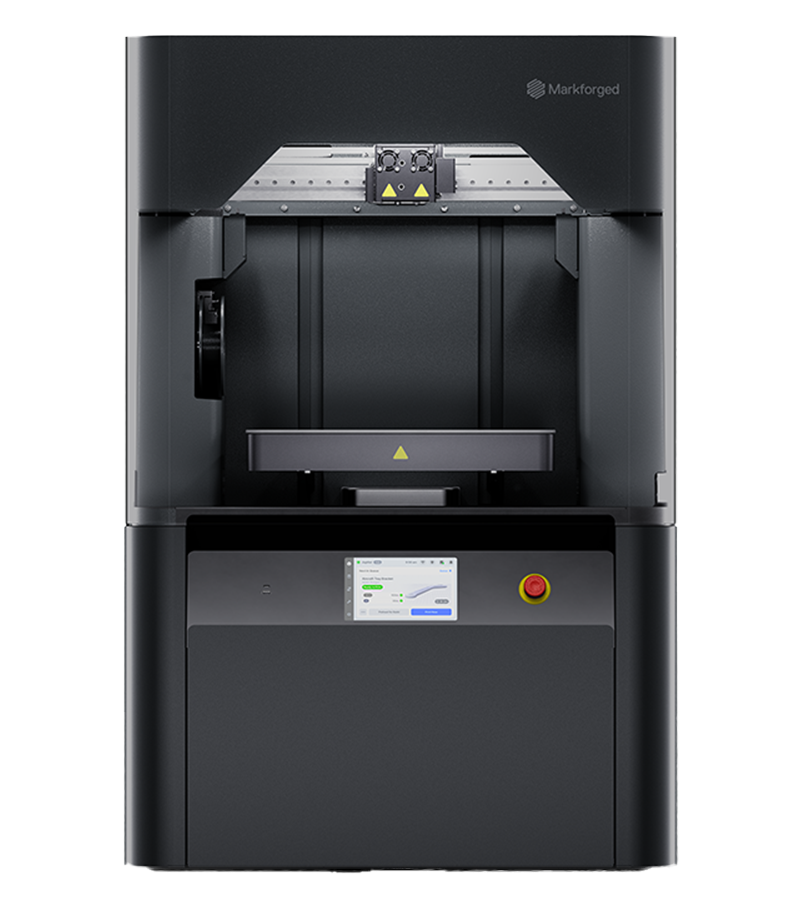

The Most Versatile Tool for Your Factory Floor

Print the right part every time

Our cutting-edge design encompasses all aspects, from the advanced motion system to the powering software, ensuring unparalleled accuracy and strength. With the added support of Simulation and Inspection software, you can trust that FX10 will consistently produce verified parts that meet even the most demanding factory floor standards.

Vision Module and Laser Micrometer

Two print head-mounted optical sensors

Experience the power of two print head-mounted optical sensors. These sensors enable in-print dimensional validation and machine calibration for precise and accurate printing. But that's not all! The FX10 also boasts a brand new Vision Module. This module captures detailed images of calibration parts, allowing you to optimize the printer's performance to perfection. Embrace excellence with the FX10 and elevate your printing experience.

Advanced Material Chamber

Four separate material chambers

The inboard material chamber is designed with four separate compartments, each one sealed, to store spools. This innovative design allows for automatic material changeover and quick spool loading, minimizing the need for user intervention.

Large Touchscreen

Impressive 7" touchscreen display

The FX10 has an impressive 7" touchscreen. Experience the convenience of starting builds, monitoring machine status, controlling the machine manually, and initiating automated calibration routines all from one centralized location. Simplify your workflow with the FX10.

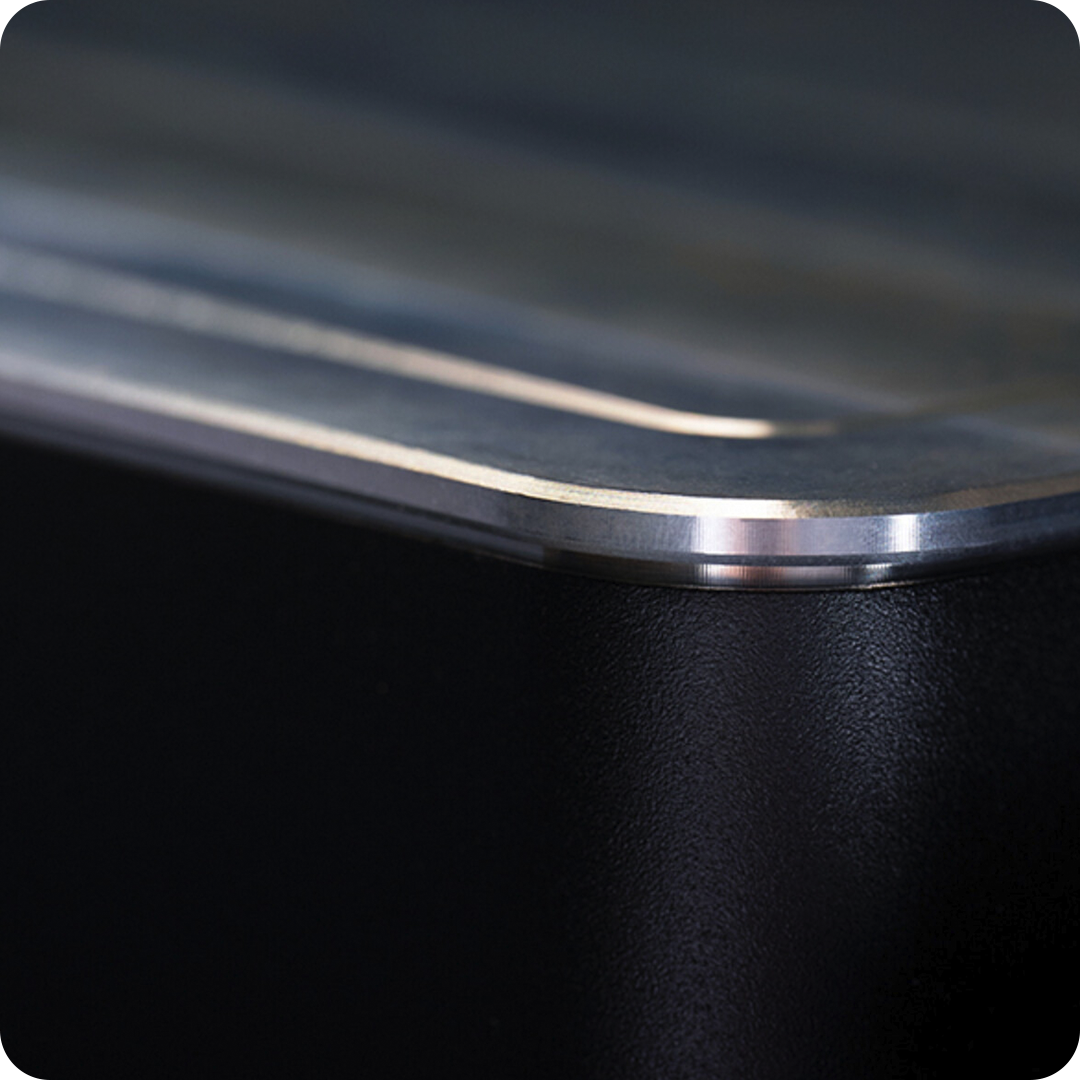

Heated Build Chamber and Vacuum Bed

Accurate calibration for perfect prints

Experience high-speed, high-quality 3D printing. With its spacious chamber heated to 60°C, this advanced printer ensures exceptional results. The precision-engineered aluminium vacuum bed, featuring laser-scanned grooves and a heated surface, guarantees accurate calibration for perfect prints.

Related Products

FX20

The FX20 isn't just a large-format 3D printer; it's a game-changer. Imagine: massive builds printing lightning-fast in its expansive heated chamber, crafted from high-performance ULTEM™ reinforced with continuous carbon fibre, ready to soar or conquer the toughest industrial demands.

Beyond its size and speed, the FX20 is precision-engineered for production. Sensor-driven and user-friendly, it delivers breakthrough reliability and consistent quality, making industrial 3D printing smoother and more accessible than ever. With the FX20, challenges shrink and possibilities soar.

Prepare to unlock industrial innovation and redefine what's possible.

X7

The X7 carbon fibre 3D printer is a game-changer, empowering engineers and designers to unleash industrial-grade innovation at an unheard-of pace.

Ditch the slow pace of machining and print parts as strong as aluminium in hours. Continuous carbon fibre reinforcement unlocks a new realm of possibilities, allowing you to replace metal components and push the boundaries of what's printable. Laser scanning delivers near-perfect surface finishes and repeatability you can trust, ensuring industrial-grade accuracy and reliability at every turn.

The X7 is more than a 3D printer; it's a revolution in manufacturing. Experience the future where innovation happens on demand.

Mark Two

Transform your workbench into a powerhouse of innovation. The Mark Two carbon fibre printer lets you print parts as strong and stiff as machined aluminium, right on your desktop. Ditch slow, expensive metalworking and unlock lightning-fast fabrication of robust jigs, tools, and production-ready prototypes.

Built for relentless performance. The Mark Two isn't just fast; it's an investment in the future. A rock-solid unibody aluminium chassis and precision-machined components ensure tireless reliability, while Onyx, our micro carbon fibre nylon, delivers an unmatched surface finish for stunningly precise parts.

Break free from the limitations of traditional manufacturing.

U.S. Air Force: Cannon Air Force Base

The Facility

Cannon Air Force Base, home of the 27th Special Operations Wing (27 SOW), lies in the high plains of eastern New Mexico, near the Texas Panhandle. The 27 SOW employs specialized aircraft and highly trained airmen to execute and support special ops missions around the world. Within the 27 SOW, the 27th Special Operations Support Squadron (27 SOSS) supports deployment, employment, planning, and combat training for specific squadrons and other flying operations.

Every year, the 27 SOSS combat training unit sets up and executes more than 300 mission scenarios. “Our training facility offers the closest thing to an actual battle without it being life-threatening,” says Lejay Colborn, the 27 SOSS Range Support Planning and Operations Specialist, and a retired Navy Explosive Ordnance Disposal (EOD) technician. A vast amount of equipment is needed to make each training scenario a reality. Colborn and his teammates must rapidly build devices and stage each environment to match specific combat zones. As part of this process, they use everything from technical and up-armoured vehicles to simulated explosives and bombs.

“Our section has over 250 years of combined military experience from each branch of the U.S. Armed Forces. We rarely run out of ideas for combat training scenarios.”

The Challenge

The 27 SOSS combat training section is all about readiness, relevance, and resiliency. They are responsible for ensuring their equipment is reliable and available at a moment’s notice. If a part or device breaks, the team must quickly replace or fix it to minimize disruption of ongoing training missions. Given the significant amount of wear and tear on combat equipment, the need for replacement parts is constant.

Possibly more important than having fast access to replacement parts is having fast access to more durable and higher-quality equipment. Many items used by the combat training section don’t always fit the team’s specific needs. As a result, they often have to modify equipment to make it more lightweight, and durable, or add and enhance specific features. According to Colborn, he needs “equipment-grade materials and something high-temperature and high-strength — like Onyx reinforced with fibreglass, carbon fibre and Kevlar, compared to a PLA or ABS machine.” The goal is to deliver necessary replacement items on the fly and, when needed, customize — or even create — new items so they more readily fit whatever scenario the team is in.

“When you’re deployed and you break something or try to get it replaced, it can be weeks before you get a new part in hand.”

The Solution

Lejay Colborn had prior experience with 3D printing thanks to the on-site Air Force Repair Facility. He even used the facility printer for some smaller jobs. But as his section’s demand for more sophisticated and durable parts increased, he decided to set up a 3D print shop within the combat training section. After extensive research, the squadron invested in a Markforged X7 printer. The benefits were almost immediate.

Airmen typically carry packs of 80 lbs or more in combat training scenarios. Under those circumstances, any load weight reduction goes a long way towards improving airman stamina and agility. The combat training unit decided to 3D print many of the tools used by airmen in the field. The tools, printed with Onyx — a carbon fiber filled nylon material — were more durable and lighter than their conventional counterparts.

Simulated combat, like real combat, can happen at any time of day — or night. That’s why most training kits include night vision goggles (NVGs). The goggles are held in place by NVG mounts affixed to the top-front of airmens’ tactical helmets. Unfortunately, NVG mounts are vulnerable to damage due to user error and impact. A single replacement mount can range from $100 to several hundred dollars with a shipping time of a few weeks or more. Colborn realized he could solve this issue with the unit’s Markforged industrial X7 3D printer. The team used the CAD file to 3D print replacement mounts with built-in spacers to accommodate multiple helmets to include those used in force-on-force scenarios for less than $5 in just a few hours. According to Colborn, his 3D printed NVG mounts are “just as strong as the commercial, off-the-shelf aluminum ones.”

Prototyping with the X7 has also been a real game-changer in terms of improving combat training readiness. “I can print something out, test it, and see if it is going to work,” says Colborn. “There’s a huge cost savings. There’s a huge time savings. There’s a lot that makes it so worthwhile. Bringing in the Markforged printer is one of the best things we’ve ever done.”

"Bringing in the Markforged printer is one of the best things we’ve ever done.”

The Future

The combat training section continues to seek new ways to improve performance and accelerate innovation through 3D printing and design. Colborn plans to pass on to his teammates everything he learned through the Markforged Training on additive manufacturing via Markforged University. The more airmen who have knowledge and experience with 3D printing technology, the more prepared and equipped the U.S. Air Force will be, both now and in the future. The combat training section has also recently acquired a Markforged Metal X system, which will help them create hybrid carbon fibre and metal parts for combat simulation systems.

The Fastest Growing Products in Advanced Manufacturing

have arrived.

We are confident that our products and solutions will exceed your expectations.